Force sensors are interesting devices. They are important for measuring forces in different industries. To use force sensors effectively, you must know their types, features, and uses. This article will reveal the secrets of force sensors. We will explore their types and many applications.

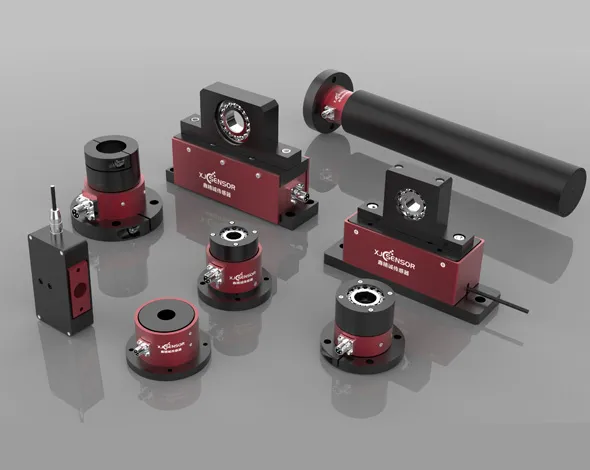

XJCSENSOR is a top force sensor manufacturer in China that you can trust.

Understanding Force Sensor Types

There are different types of force sensors for specific applications and measurements. Let’s explore some commonly used force sensor types:

Strain Gauge Load Cells

The force sensors use strain gauge technology. A strain-sensitive resistor is attached to a structural element. Applying a force makes the element change shape, which changes its resistance. This change is then measured and converted into a force reading.

Piezoelectric Force Sensors

Piezoelectric sensors generate an electric charge when subjected to mechanical stress. The sensors have crystals that produce an electrical signal when force is applied. The generated charge is measured and translated into a force reading.

Capacitive Force Sensors

Capacitive sensors measure changes in capacitance when electrodes move from an applied force. As the distance between the electrodes changes, the capacitance also varies. By monitoring this change, the applied force can be determined.

Magnetic Force Sensors

Magnetic force sensors detect changes in magnetic fields caused by applied force. They use magnetoresistive or Hall-effect technologies. When a force is applied, the magnetic elements in these sensors change. We measure changes in the magnetic field to find the force’s strength.

Optical Force Sensors

Optical force sensors utilize light-based techniques, such as strain-optic or fiber-optic technologies. We monitor how light changes to find out the force being used.

Applications of Force Sensors

Many industries use force sensors because they accurately measure force and are versatile. Here are some common applications:

Robotics and Automation

Force sensors enable robots to interact safely and precisely with their environment. Robots can do delicate tasks and work well with humans because they can feel force.

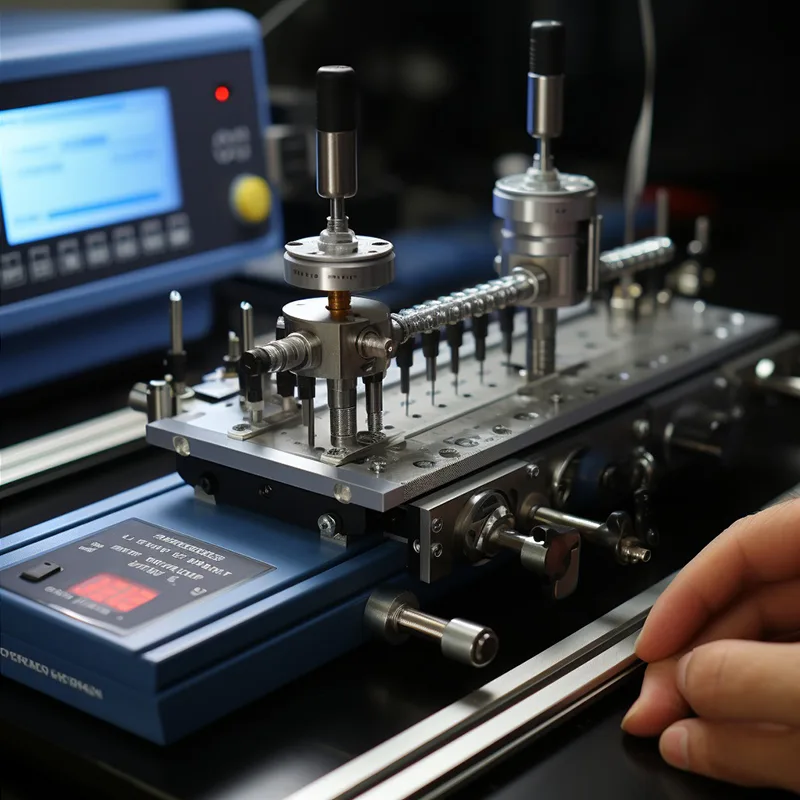

Product Testing and Quality Control

Force sensors are important in product testing. They measure forces during compression, tension, or fatigue tests to ensure quality control. They help verify the strength and durability of various products.

Automotive Industry

Force sensors are used in cars for crash tests, seat belts, suspension, and brake force. They ensure safety and optimize performance in vehicles.

Medical Devices

Force sensors are used to monitor vital signs. They also calibrate medical equipment and give feedback in prosthetics and surgical robots. They contribute to patient care and rehabilitation processes.

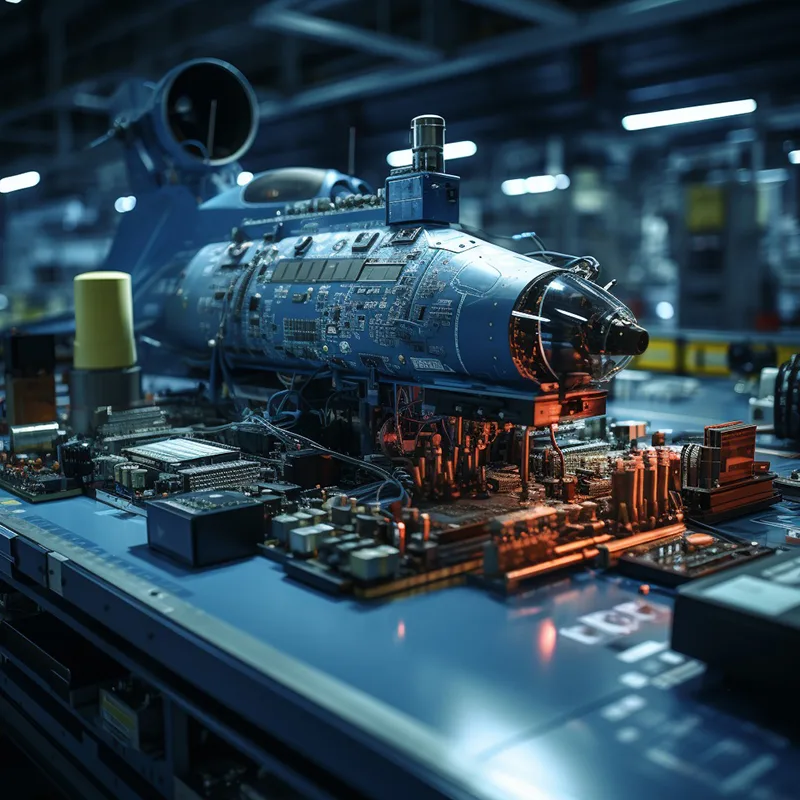

Aerospace Industry

Force sensors are instrumental in structural testing, aerodynamics research, and aircraft maintenance. They help evaluate the integrity and performance of aircraft components.