X-ZL11 Series Flange Tension Sensor

It is installed in pairs at the end of the measuring roll, which can accurately detect the resultant force produced by pulling the material at the wrapping angle. It is designed to install the pillow block on the sensor, which is easy to replace and install the pillow block and roller. Accurate and stable signal with resistance strain formulaprinciple. Compact structure and little deformation.

Category

X-ZL11 Series Flange Tension Sensor

Features

● Built-in self-aligning bearing (two ends are not in the same surface) which can compensate for bearing expansion and misalignment;

● Self-aligning bearing is easy to install;

● Built-in new mechanical 10 times anti-overload protection;

● Minor temperature drift,good non-linearity and repeatability;

● Small size, little space required for installation;

● Two installation directions are available;

● Standard M12*1 plug

Description

XJC-ZL11 series flange tension sensor is installed inpairs at the end of the measuring roll, which can accurately detect the resultant force produced by pulling the material at the wrapping angle. The sensor comes with a selfaligning ball bearing, which can compensate for mechanical error caused by installation and avoid mismeasurement. The bearing disassembly is simple and easy to operate. Multiple bore diameters are optional(15mm, 17mm, 20mm, 25mm etc.) Standard and flange installation are available.

Technical Parameter

| Rated output | 1.5±0.2%mV/V | Non-linearity | 0.3% F.S. |

| Repeatability | 0.15%F.S. | Zero balance | ±2% F.S. |

| Operating temp range | -20~80°C | Compensated temp range | -10~40°C |

| Temp effect on zero | 0.02%F.S/°C | Insulation | ≥2000MΩ/100VDC |

| Recommended excitation voltage | 5~10VDC | Limit load | 1000%F.S. |

| Cable size | φ5x5m | Protection class | IP65 |

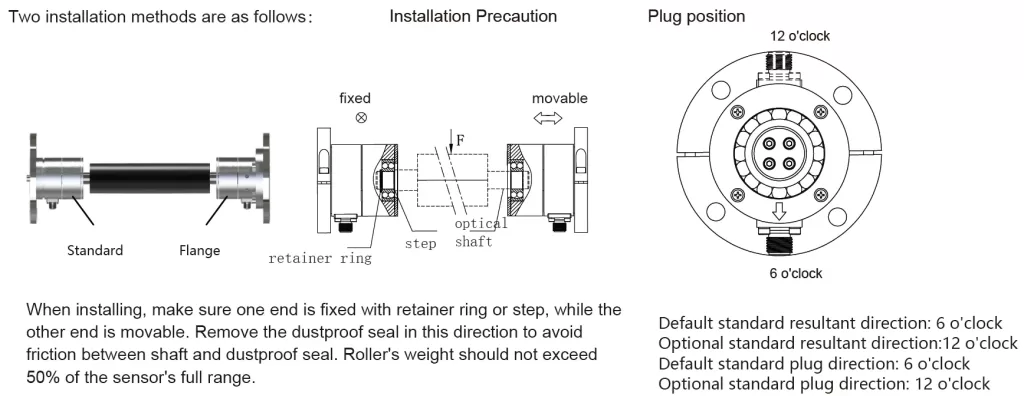

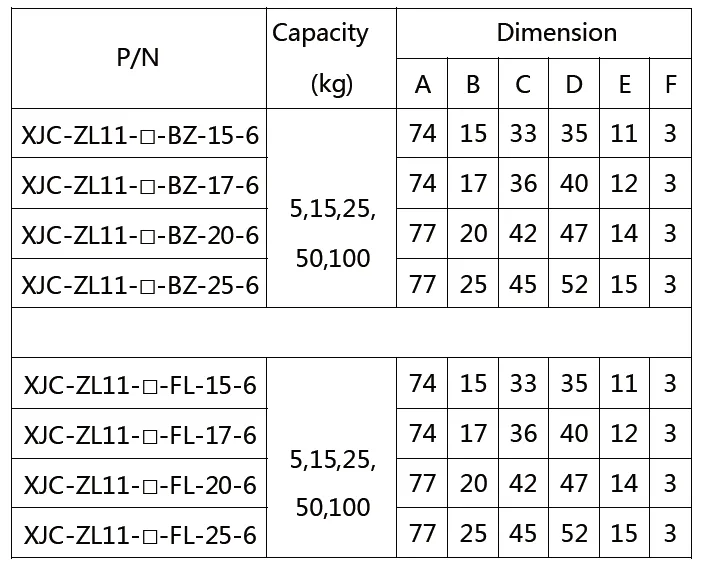

Dimensions

Note: The rated load is only referred to a single sensor’s value, and it should be twice of the above value if sensors are installed on both sides.

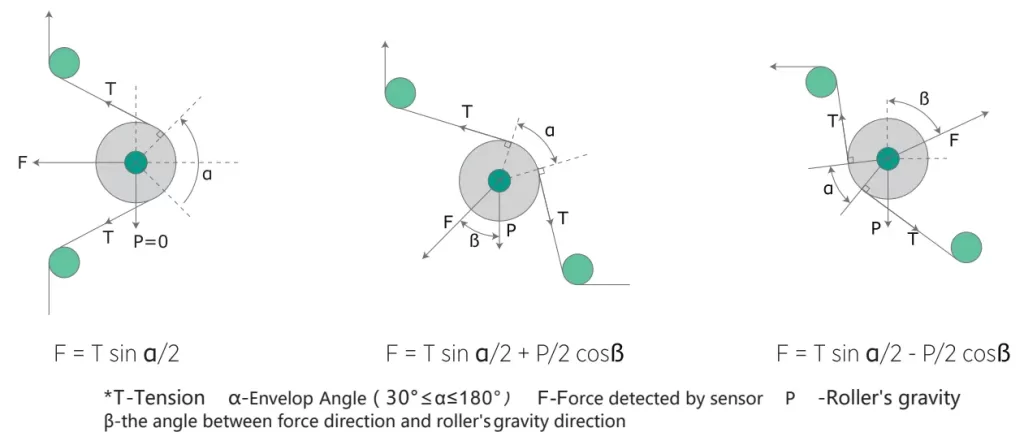

Force calculation

Installation