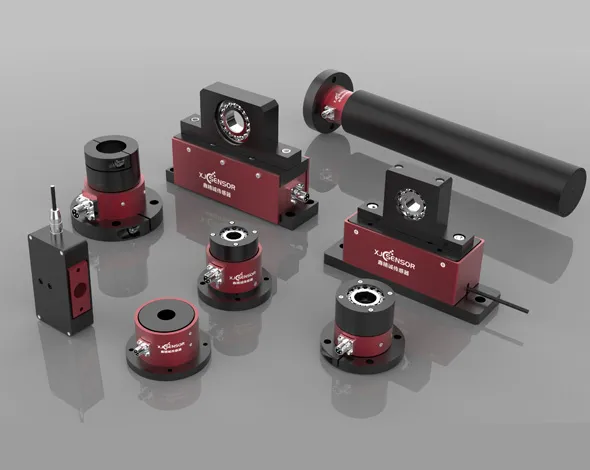

Have you ever thought about how industries get such accurate force readings for important tasks? XJCSENSOR Company’s leading-edge load cell force sensors provide the answer.

XJCSENSOR specializes in accurate load cell force sensors for a range of industrial uses. These sensors are designed to work flawlessly, giving precise measurements in many applications. Whether it’s in making products or advanced research, these sensors are key.

XJCSENSOR’s sensors are the top choice for those who need reliability. Using advanced technology, they meet the strict requirements for precision and dependability set by industries.

Key Takeaways:

- XJCSENSOR specializes in high precision load cell force sensors.

- These sensors are crucial for accurate and reliable force measurement.

- XJCSENSOR serves a wide range of industrial applications.

- The focus on quality ensures high performance and dependability.

- Industries benefit significantly from XJCSENSOR’s precise load cell technology.

An Introduction to Load Cell Force Sensors

Load cell force sensors turn mechanical force into an electric signal. They use technologies such as hydraulic and piezoresistive. Yet, the strain gauge load cell is most common for its accuracy and dependability.

What is a Load Cell Force Sensor?

A load cell force sensor measures force by noticing how much something changes in size. For example, the strain gauge load cell has four parts that measure this change.

They are put in a way that makes force measurement very accurate. It can measure with very small error, from 0.03% to 0.25%.

Applications of Load Cell Force Sensors

Load cells are used in many fields because they are flexible. They help make sure products are up to standard. In weighing systems, they give exact measurements, crucial for cars and planes.

They’re also key in safety tests. Here, their precision is very important.

| Load Cell Type | Accuracy (Full Scale) | Key Features |

|---|---|---|

| Strain Gauge Load Cell | 0.03% to 0.25% | High accuracy, Wheatstone bridge construction |

| Hydraulic Load Cell | 0.25% or better | Suitable for process weighing applications |

| Pneumatic Load Cell | Varies | Explosion-proof, insensitive to temperature variations |

| Piezoresistive Load Cell | N/A | High-level output signal |

| Bending Beam Load Cell | Varies | Low profile, used in tank weighing |

| Canister Load Cell | N/A | All stainless steel, hermetically sealed |

Thanks to modern technology, load cell sensors improve accuracy and safety. They’re crucial in today’s industries. To learn more about load cells, visit Omega’s guide.

Types of Load Cell Force Sensors

It’s important to know about the different load cell force sensors to pick the right one. Each type measures various forces accurately and reliably.

Compression Load Cells

A compression load cell measures pushes or compression. Used in many industries, they are accurate and stable. They work in things like scales. Their electrical signals are small and need boosting to be useful.

Tension Load Cells

A tension load cell measures pull or tensile forces. They are vital in pulling force measurement settings. Fields like aerospace and automotive use them for their precision. These sensors are precisely calibrated to ensure accuracy consistently.

3 Axis Force Sensor Load Cells

The 3 axis force sensor load cell can measure force in three directions at the same time. This is essential for complex force measurement tasks. Industries such as healthcare and agriculture find them indispensable for their versatility. They help in detailed force analysis and control.

Transducer Techniques is an industry leader in load cell and torque sensor manufacture, offering a variety of load cell types to suit different industrial needs.

There are many load cell types such as Strain Gauge, Compression, Tension, and others. Their output signals are prepared for further processing. Special load cells are also made for unique uses where specific measurements are required.

| Type | Measurement | Application |

|---|---|---|

| Compression Load Cell | Compressive Forces | Industrial Weighing, Scales |

| Tension Load Cell | Tensile Forces | Aerospace, Automotive |

| 3 Axis Force Sensor Load Cell | Multi-Directional Forces | Healthcare, Manufacturing |

How Load Cell Force Sensors Work

Learning how load cell force sensors work helps us make the most of them. It’s all about the advanced parts and materials they are made with.

The Role of Strain Gauges

Strain gauges are key for the accuracy and trustworthiness of these sensors. They define how much an object changes form when force is applied. This change creates an electrical signal that lets us measure force with great accuracy.

Mechanical Construction and Materials

Load cells are built using strong materials like steel or aluminum. These materials are picked carefully. They help the sensors be very sensitive and measure a wide range of forces. This makes these sensors very accurate and durable in tough places.

Advantages of Using High Precision Load Cell Force Sensors

High precision load cell force sensors are very useful in the industry and science. They can give very accurate and reliable measurements. This makes them really important for jobs where accuracy is key.

Accuracy and Reliability

One big plus of these sensors is how accurate and reliable they are. They ensure every measurement is precise, which is vital for quality and safety. Sensors like those from XJCSENSOR are known for their consistent top-notch performance.

Cost and Efficiency

These sensors don’t just do a great job, they are also budget-friendly. They save money upfront and in the long run. Their efficient design means they need less upkeep. This all lowers costs, making them a smart choice for businesses looking to save without sacrificing on quality.

Load Cells vs. Force Sensors: Key Differences

It’s important to know the differences between load cells and force sensors. This understanding helps in choosing the best tech for your needs. Even though they’re sometimes used the same way, they have different designs and functions.

Mechanical Design Differences

Load cells focus on the strain gauge to ensure very accurate weight measures. They’re used in scales and systems that need precise load readings. On the other hand, force sensors use various technologies, like piezoelectric or capacitive, to measure forces like tension, compression, or torque.

Performance Metrics

Strain gauge load cells are well-known for their high accuracy and repeatable weight measures. However, force sensors offer a wider range of measurement options. How well these devices work is based on specific needs. Hysteresis, linearity, and stability are key in how effective both types are.

| Aspect | Load Cells | Force Sensors |

|---|---|---|

| Design Principle | Strain Gauge | Varies (Piezoelectric, Capacitive, etc.) |

| Common Application | Weight Measurement | Diverse Force Measurement |

| Performance of Strain Gauge Load Cell | High Precision and Repeatability | Varied, Depends on Technology Used |

Understanding Load Cell Calibration

Load cell calibration is crucial for measuring force accurately and keeping the sensor working well. It’s needed because many things can wear on the cell over time. Things like stress and the environment change how well the load cell works.

In calibration, accurate reference weights test the load cell in known conditions. This way, we make sure the sensor stays reliable for measuring force correctly. Regular calibration makes sure the load cell’s measurements are always close to the actual force used.

XJCSENSOR supports this calibration process. It helps increase the sensor’s life and keep it working right. Calibrating isn’t just for following rules, but also for making sure your equipment works without errors. Doing this avoids unexpected stops and lets you measure force precisely when you need to the most.

| Aspects | Benefits |

|---|---|

| Regular Calibration | Ensures consistent load cell precision |

| Use of Reference Weights | Verifies sensor output accuracy |

| Support from XJCSENSOR | Extends life span and measurement integrity |

| Preventative Maintenance | Avoids unexpected downtimes |

By knowing and using good load cell calibration techniques, you keep your sensors working well. This means they’re reliable for a long time, giving you accurate results when measuring force.

Digital Load Cells: The Future of Force Measurement

The move to digital load cells is changing how we measure force. Leading this change is Interface, a company with a history dating back over 50 years. They are now big on digital load cells, which use Wifi and Bluetooth® for data transfer.

Advantages of Digital Load Cells

Digital load cells bring many benefits, specifically for vital industry needs. They are better at handling noise, which makes measurements more accurate in tough settings. Calibration is simpler, cutting down on maintenance and downtime. Plus, these sensors are great at quickly processing data, making force measurements better and faster.

How Digital Load Cells Work

To use digital load cells effectively, knowing how they work is key. These sensors turn force into digital signals, thanks to their built-in electronics. They use cutting-edge technology like multipoint data collection and real-time processing to ensure precision and reliability.

- Wireless data transmission via WIFI and Bluetooth®.

- Improved noise immunity for accurate measurements.

- Expanded temperature ranges for diverse applications.

The shift to digital tech is part of a larger movement in the industry. Now, there’s a growing need for systems that can measure force, torque, and more all at once. This change shows how the industry is aiming for solutions that work well in many areas, from space tech to electric vehicles.

Discover more about the future of load cell measurement and the latest advancements in force sensor technology.

The latest stats highlight a proactive effort in developing new products. Companies like Interface are really pushing force measurement technology forward. They’re improving accuracy, making load cells effective in more settings, and enhancing their capabilities. This drive makes it clear that the future of measuring force is digital, offering more efficient solutions for a range of industries.

Force Measurement Sensors for Industrial Applications

XJCSENSOR’s load cell force sensors are key in many load cell applications across different fields. They are critical for automating tasks and increasing accuracy in industries like manufacturing, packaging, and infrastructure testing.

“The robustness and precision of XJCSENSOR’s force measurement sensors greatly improve manufacturing lines, ensuring consistent quality and efficiency.” – Industry Expert

The industrial use of load cell force sensors is broad, fitting various needs. They help check force in packing or verify infrastructure safety. This shows their wide use.

These sensors can work in many places:

- Manufacturing: They ensure force measurements are exact, cutting down mistakes.

- Packaging: They watch over forces to keep products safe.

- Infrastructure Testing: They test structure strength for safety and rules.

Here’s a look at how force measurement sensors help in different fields:

| Industrial Application | Benefits |

|---|---|

| Manufacturing | High precision, enhances production quality. |

| Packaging | Accurate force regulation, prevents package damage. |

| Infrastructure Testing | Reliable measurements, ensures structural safety. |

XJCSENSOR’s force measurement sensors are experts in their field. They help make processes better and ensure exact results, making them vital in many load cell applications.

Micro Force Sensor Load Cells: Small Size, Big Impact

Micro force sensor load cells are changing the game in cramped spaces. They’re key in industries needing tiny yet precise force measurements. We mostly see them in leading-edge medical tools and hand-sized robots. These sensors provide top-tier precision, ensuring solid data in crucial settings.

Applications of Micro Force Sensors

Miniature load cell applications rely heavily on micro force sensors. They play a big role in making the latest in medical gear. Think surgical robots, replacement limbs, and infusion pumps. These devices need exact force details to function perfectly.

In the world of robotics, these sensors are key for small yet powerful machines. They help control robots and other automated gadgets. This fine control is what makes these gizmos work right in such small sizes.

Performance and Accuracy

Micro force sensor load cells excel in providing accurate and tough performance. FUTEK’s models can hit nonlinearity and nonrepeatability as low as ±0.02% of Rated Output. This is critical, for instance, in testing rocket thrust.

They’re built tough, with materials like aerospace stainless steel or aluminum. This gives them strength and reduces hysteresis. They keep working, even in rough conditions like extreme heat or chemicals.

Calibration keeps them spot-on. FUTEK’s calibration corrects zero errors and more using precision tech. They’re checked off against the strict ISO 17025 standards. This means they’re top-notch for important jobs.

In brief, sensors like FUTEK’s are the go-to for tight spaces needing perfect measurements. They’re vital for accuracy in crucial settings.

Load Cell Accuracy: Ensuring Precise Measurements

Making sure load cells are accurate is key for precise measurements in many areas. There are different things that can change a load cell’s performance. These can be due to the environment or the load cell’s own qualities. Knowing about these factors helps improve how load cells work.

Factors Affecting Accuracy

Many things can lower the load cell accuracy:

- Temperature Variations: When temperatures change, load cell parts might expand or shrink. This can mess up the readings.

- Mechanical Installation: Putting them in the wrong way can cause problems, like the load not being straight or the surface they’re on moving.

- Electrical Interference: Electrical fields or static can mess with load cell readings, making them less precise.

- Load Cell Quality: How well a load cell is made and what it’s made of is a big part of how precise it is.

Improving Accuracy

To make load cells more precise, we need to deal with these issues. Some ways to get better readings are:

- Temperature Compensation: Use load cells that adjust for temperature changes on their own.

- Proper Installation: Put them in right using the maker’s instructions to avoid mistakes from the start.

- Shielding and Grounding: Protect load cells from electrical issues by using the right shielding and grounding methods.

- Regular Calibration: Keep them accurate by checking and adjusting them every so often.

- Quality Selection: Get good load cells from trusted makers like XJCSENSOR. They’re more likely to last and stay accurate.

Using the strategies above can really boost the load cell accuracy. This means better, more precise measurements wherever they’re used.

Innovative Applications of Load Cell Force Sensors

Load cell sensors are changing the game in several industries. They are especially important in the medical, aerospace, and automotive fields. These sensors make things better in many ways, like driving new ideas and making us safer.

Medical Devices

Load cells are making medical devices more precise than ever before. Think about surgical robots or prosthetic limbs. They’re better because of these sensors. With load cells, doctors can do their work more accurately, making surgeries safer and improving how people recover. These sensors are also key in machines that keep an eye on patients. They give real-time info, which means better healthcare outcomes.

Aerospace and Automotive Industries

For airplanes, load cells are essential. They check if planes are safe and fly well. They watch over important parts like wings and the body of the plane. This happens during building and after a plane has been flying for a while.

Cars also use load cells a lot. For safety, they are in crash tests. They are also part of making cars during assembly, which makes the process more precise. By using these sensors, cars become safer, work better, and are of higher quality.

Check out the table below to see more about how load cell sensors are used in different fields:

| Industry | Application | Benefit |

|---|---|---|

| Medical Devices | Surgical Robots | Improved Precision |

| Medical Devices | Prosthetics | Enhanced Responsiveness |

| Aerospace | Structural Integrity Monitoring | Increased Safety |

| Aerospace | Performance Testing | Better Reliability |

| Automotive | Crash Testing | Enhanced Safety Standards |

| Automotive | Manufacturing Automation | Improved Quality Control |

Conclusion

XJCSENSOR leads in high precision load cell force sensors. These sensors are top-notch for uses in many fields, like aerospace and medical areas. They aim at top accuracy and reliability. This has made XJCSENSOR known for its quality.

Using XJCSENSOR’s tech comes with big advantages. It helps keep critical measurements accurate in manufacturing. It also boosts safety in construction. The world’s need for exact, affordable, and efficient measuring tools is growing. XJCSENSOR is ready to meet these needs.

In summary, XJCSENSOR’s load cell force sensors are crucial for today’s industries. They stand out for their innovation and quality. XJCSENSOR is a top choice for those aiming for the best in force measurement. The future looks bright with XJCSENSOR, promising more progress and better performance in measuring force.