Welcome to the exciting field of piezo force sensors! These advanced tools, piezoelectric force sensors, play a key role in measuring force accurately. They are essential in many areas, from aerospace to medicine, thanks to their precision.

What makes these sensors important? Their ability to detect impacts, monitor vibrations, and handle high forces is crucial. This is why they are widely used where accurate force measurement is critical. As more industries see their value, piezo force sensors are becoming even more common.

The use of piezo force sensors is diverse. They’re perfect for scientific research that requires top-notch precision. In industries that need tough, reliable sensor technology, these devices excel.

The development of piezoelectric sensor technology doesn’t stop. With many patents and new materials, these sensors are always improving. They’re prepared to face the challenges of tomorrow.

For a deep dive into the latest in force measurement tech and to explore new products like the MiniONE Pro and more, see this comprehensive guide from Bota Systems.

Key Takeaways

- Piezo force sensors excel in precise force measurement.

- They’re crucial in industries such as aerospace and medical fields.

- Many patents and material innovations support this technology.

- Their high sensitivity makes them very flexible.

- They’re always being improved to meet future needs.

The Fundamentals of Piezo Force Sensors

Piezo force sensors are amazing pieces of tech. They greatly help with measuring force. They use special materials to do this job well, serving many industries.

What is a Piezo Force Sensor?

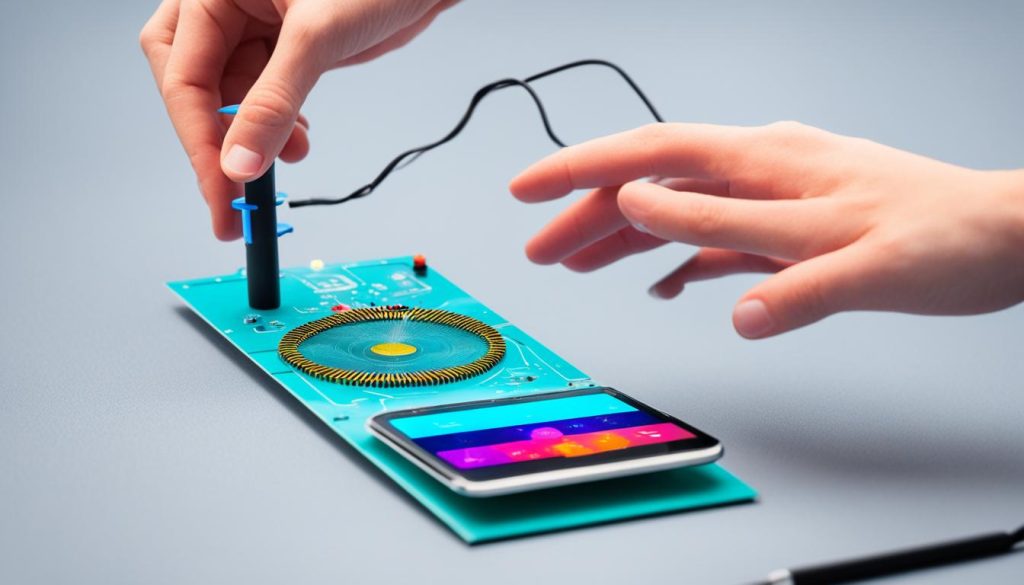

A piezo force sensor turns mechanical force into an electrical signal. It does this using piezoelectric materials. These sensors are top-notch at sensing very gentle forces. They work by putting pressure on a piezoelectric crystal to create an electric charge.

Basic Working Principle

The piezo force sensor works through the piezoelectric effect. Put simply, this means a mechanical push creates an electrical signal. This signal shows how much force there is. These sensors are super-accurate and give info in real time. This is key for tasks needing exact force measurements.

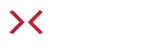

Key Components

A piezo force sensor system has many parts:

- Piezoelectric Material: This is usually a crystal or ceramic. It’s at the sensor’s core and turns pressure into electrical signals.

- Electrodes: They’re made of conductive materials. They pick up the charge from the piezoelectric material.

- Housing: This is the cover that protects the sensor’s parts from harm and the environment.

- Signal Conditioning Circuitry: These are the fine-tuning parts that make the sensor’s signals easy to understand.

These parts join forces to make the piezo sensor work well. They ensure accurate measurements of force.

Types of Piezoelectric Force Sensors

Different jobs need different piezoelectric sensors to measure force. These sensors work in compression, shear, or torsion ways. Choosing the right one is important for accurate readings.

Compression Mode Sensors

Compression mode sensors check forces pushing straight down on them. They’re great for spots that must be super clean or where things get made. This is because they work really well with pressure changes. They measure force very precisely because as pressure changes, so does the electrical charge, giving you exact numbers.

Shear Mode Sensors

Shear mode sensors measure forces sliding across their surface. They’re perfect when there’s a lot of shaking or moving. Places like making cars or planes use these sensors to watch how much force is happening in their machines and structures.

Torsion Mode Sensors

Torsion mode sensors notice twisting or spinning forces. They’re key in jobs that need to measure how much something turns. Think about robots or big machines – these sensors make sure all the moving parts are working as they should.

Advantages of Using Piezoelectric Technology

Piezoelectric technology in force sensors offers many strong points. It includes high sensitivity and broad frequency response. Moreover, these sensors are really tough and reliable. Now, let’s dive into why they are top-notch for measuring force.

High Sensitivity

Piezoelectric sensors are ultra-sensitive. They catch even the tiniest forces with great accuracy. Think of cases in aerospace and medical fields where precision is key. These sensors turn small changes into clear electric signals, providing unmatched precision.

Wide Frequency Range

Another big plus is their ability to work across a wide frequency range. This means they fit in with many jobs – from tracking low-frequency earthquakes to watching high-speed machines. Their broad frequency use means they can help out in many different situations.

Durability and Reliability

One of the biggest draws for piezoelectric tech is how tough and reliable it is. These sensors can take on harsh conditions and keep working. They are great for places with extreme temps, lots of shaking, or dirty air. Because of this strength, they perform well for a long time.

| Advantage | Description | Application Example |

|---|---|---|

| High Sensitivity | Detects tiny forces with great detail | Medical diagnostics, aerospace engineering |

| Wide Frequency Range | Works across all ranges of frequencies | Seismic monitoring, industrial machinery |

| Durability and Reliability | Handles rough conditions for ongoing use | Extreme temperature environments, high-vibration settings |

Piezo Force Sensors in Industry Applications

Piezo force sensors are making big changes in various industries. They boost accuracy and efficiency. These sensors meet specific needs in different fields well.

In aerospace, they watch over stress in parts and keep things working perfectly. For medical tools, they ensure the right amount of force, improving care and outcomes. In short, they’re crucial for many devices we rely on.

They’re key in the automotive world too, in airbags and braking systems. Their precision helps these systems work safely. In manufacturing, they check products’ quality by measuring force accurately.

Piezo sensors are a big part of advanced sensor tech. They’re used in tough conditions for reliable, strong results. Their value shines in making industrial work smoother and better.

- Aerospace: Monitoring stress and ensuring structural integrity.

- Medical Devices: Enhancing precision in surgical instruments and diagnostics.

- Automotive: Key component in airbags, brakes, and engines.

- Manufacturing: Vital for quality control processes.

“The implementation of piezo force sensors in industrial applications revolutionizes the way we approach precision measurement, making operations more efficient and reliable,” said a leading industry expert.

Innovative Applications of Piezo Force Sensors

In the past few years, piezoelectric force sensors have advanced greatly. They’re being used in many innovative applications today. One major area seeing the benefits is healthcare. These sensors are key in modern medical devices, offering precise measurements essential for things like robotic surgeries and prosthetic development.

The automotive field is also utilizing this new technology for better safety and performance. For example, sensors in cars monitor tire pressure and how the engine is doing. This data helps make driving safer and more efficient. These sensors have also entered the consumer electronics world, improving touch screens and haptic devices for better user experiences.

In entertainment, piezoelectric sensors are changing how we experience virtual reality (VR). They’re being put in VR gloves and suits to recreate touch and force feedback. This not only makes games and VR experiences more immersive, but it also aids in training people in areas like defense and sports.

Industrial automation is a field ripe for these sensors too. Using this new technology, factories maintain precise force control in various processes. This precision results in better products and less waste, promoting more sustainable manufacturing.

Here’s a quick look at the impact of these sensors in different applications:

| Application | Sector | Impact |

|---|---|---|

| Robotic Surgery | Healthcare | Enhanced precision |

| Tire Pressure Monitoring | Automotive | Improved safety and efficiency |

| Haptic Feedback | Consumer Electronics | Better user interaction |

| VR Touch Simulation | Entertainment | Immersive experiences |

| Robotic Force Control | Industrial Automation | Higher product quality |

The new technologies are continually broadening the use of piezoelectric force sensors. Each new application brings us a step closer to a future filled with efficient, accurate, and creative solutions in our daily lives.

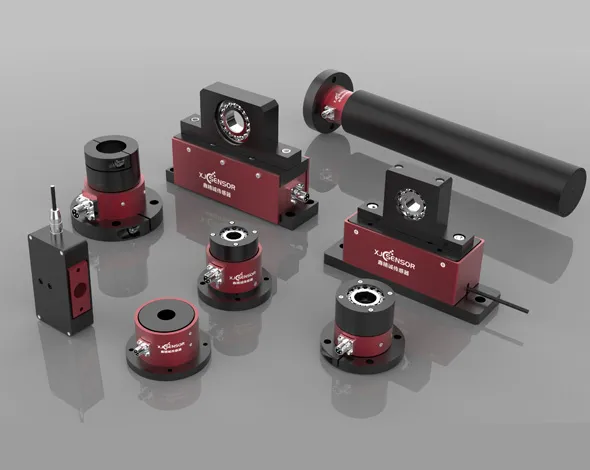

How XJCSENSOR is Leading Innovation

At XJCSENSOR, we’re at the leading edge thanks to our research and development. We provide custom sensor solutions that meet our clients’ needs perfectly. This puts us in the spotlight for piezoelectric force sensors.

Research and Development

Our focus at XJCSENSOR is on research and development. We use the latest tech and a skilled team to improve our sensors. This means we offer better sensors that you can trust in many jobs.

Custom Sensor Solutions

We know everyone’s needs are different. So, we’re great at offering custom sensor solutions. When you work with us, we make sensors just for you. This way, you get accurate measurements and top performance.

Client Success Stories

XJCSENSOR’s success is shown through our client stories. We’ve teamed up with top companies and helped them do better work. This shows our deep knowledge and how we care about our clients. It’s about growing together.

Choosing the Right Piezoelectric Force Sensor

Selecting the right piezo force sensor is key for top performance. We’ll review critical steps in choosing a sensor.

First, understand what your application needs. This step will point you towards the best sensor. Whether you need high sensitivity or broad frequency response, pinpointing these needs is essential.

Next, understand the piezoelectric technology’s features. The environment it will operate in, the force it will measure, and how accurate it needs to be are crucial. Here are key points to consider:

- Application Requirements: Know the accuracy, environmental needs, and operational frequency your project requires.

- Sensor Characteristics: Look at sensitivity, bandwidth, and how durable the sensor is. Finding the right fit is crucial for success.

- Performance Specifications: Check the measurement range, accuracy, and hysteresis. These details are key for making sure the sensor can handle the job.

Using manufacturers’ comparison charts can make choosing easier. These resources dive into different models, highlighting key features that match your needs. Reading expert opinions can also provide valuable insights.

| Criteria | Description | Importance |

|---|---|---|

| Application Requirements | Specific needs such as sensitivity and operational environment | High |

| Sensor Characteristics | Features like sensitivity, durability, and bandwidth | Medium |

| Performance Specifications | Detailed performance metrics ensuring operational readiness | High |

By carefully going through these points and using the vast info available, like buying guides and expert advice, you’ll find the perfect piezo force sensor. This will meet your needs with confidence.

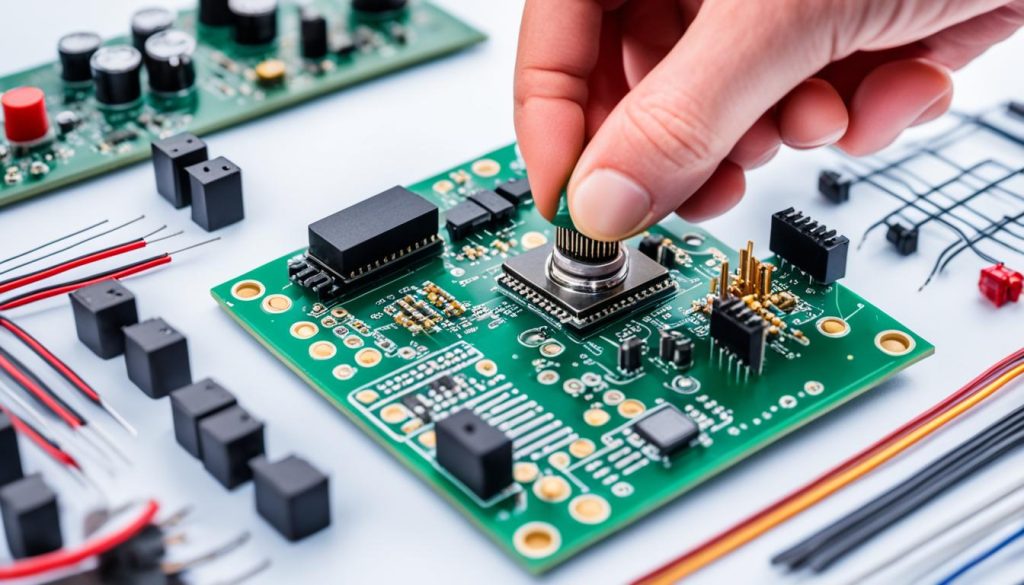

Integration and Installation Tips

Getting your sensors set up right means paying close attention. We’ll go over how to mount them, what wires to use, and the best way to calibrate. This ensures your piezo force sensors work at their very best.

Mounting Techniques

Choosing the right way to mount sensors is key. Make sure the spot is not only clean but also smooth. This prevents any issues with the readings. Use fixtures made for these sensors to keep them steady and accurate. Depending on your setup, you can either stick them on or secure them with screws.

Wiring Considerations

Using the right wires helps avoid problems with your data. Always pick shielded cables to stop other signals from messing things up. Also, keep an eye on how long the cables are. Too much length can mess with the signal. Oh, and don’t forget to properly ground the sensors to keep the noise low.

Calibration Procedures

Keeping your sensors well-calibrated is a must for accurate results. Start in a place where vibrations won’t interfere. Then, test them with known weights to make sure they’re reading correctly. Do this check regularly to catch any changes in performance. With careful calibration, your sensor will keep giving spot-on measurements.

| Aspect | Recommendation |

|---|---|

| Mounting | Ensure surface cleanliness, use appropriate fixtures |

| Wiring | Use shielded cables, minimize cable length, proper grounding |

| Calibration | Perform in controlled environment, use standardized weights |

Challenges and Solutions in Using Piezo Sensors

When discussing piezo sensors, we must understand their challenges. It’s key to know the common hurdles and how to solve them with piezoelectric solutions. Environmental factors pose a significant challenge. They can affect the sensor and its performance over time. A solution is to use strong housing designs. These designs protect sensors from bad weather and other harsh elements. This step boosts their life and durability.

“Ensuring precise and reliable measurements even in challenging environments is crucial for piezoelectric sensor technology.”

Signal noise is another big issue that affects accuracy. Luckily, we have advanced techniques to deal with this. Filtering and processing algorithms help keep the data clean and precise. Ensuring proper grounding and shielding also makes sensors more reliable.

Lastly, continuous monitoring and maintenance are key for sensor health. Regular calibration and testing keep sensors working well for a long time. With innovative solutions, we tackle the challenges. This ensures piezoelectric sensors always deliver accurate results, even in tough situations.

Future Trends in Piezoelectric Sensor Technology

The world of piezoelectric sensor technology is always changing. New research and innovations are driving it forward. Looking ahead, we see several important trends. These show where this exciting field might go.

Advancements in Materials

Material science is a key area for progress. New piezoelectric materials are being developed. They make sensors more sensitive, durable, and flexible. This advancements in materials means the sensors can do more. They become better for many uses.

New Applications and Use Cases

Sensor technology is improving all the time. Because of this, piezoelectric sensors are being used in more places. They help in medical tests and on farms. Every day, we find new ways to use them. These advancements are solving big problems and making things work better. They show how powerful these sensors are for creating new systems.

Improved Manufacturing Techniques

Making piezoelectric sensors is getting better, too. New methods in making things small and precise help a lot. They make the sensors even better and cheaper. This helps meet the growing need for these sensors. It also makes them more popular.

Here’s a closer look at some key factors shaping these future trends:

| Trend | Description | Impact |

|---|---|---|

| Material Development | New compounds with superior properties | Enhanced sensor performance and durability |

| Novel Applications | Emerging use cases in diverse fields | Increased deployment and utility |

| Manufacturing Innovations | Techniques like microfabrication | Cost reduction and better quality |

As we embrace these

future trends

, the future looks bright for piezoelectric sensors. The drive for innovation keeps them leading in technology. They play an important part in many areas.

Conclusion

We’ve learned a lot about piezo force sensors. It’s clear they’re more than just for measuring force. Their many uses in different areas show how vital they are today. Thanks to new materials and sensor tech, we’re seeing amazing advancements.

This article talked about how these sensors work and their key benefits. As we’ve seen, they’re very sensitive and last a long time. Companies like XJCSENSOR are at the forefront. They help us understand how to use these sensors now and what’s coming in the future.

In conclusion, piezo force sensors have a bright future. They keep getting better and more useful. Looking forward, these sensors will keep leading to new ideas. They will play a big part in making technology better in many fields.