The accuracy of canister load cells has a big impact on industrial weighing. You might be surprised by how much.

Canister load cells play a key role in many industrial weighing tasks. They ensure force measurements are precise and reliable. We, at XJCSENSOR, know that our load cells’ accuracy affects our clients’ results. We’re dedicated to making load cells that are extremely accurate, promoting better quality and innovation in load cell technology.

Key Takeaways

- Canister load cells are crucial for ensuring precise force measurement in various industrial applications.

- Our company’s commitment to quality ensures reliable industrial weighing results.

- Various designs of load cells such as piezoelectric, strain gauge, and magnetic load cells, emphasize different force measurement needs.

- Load cells are applicable in diverse industries, including geotechnical and structural monitoring.

- Ensuring high standards of accuracy in canister load cells can significantly improve operational efficiency and safety.

Introduction to Canister Load Cells

Canister load cells are key in industry due to their sturdy build and ability to support high weights. They ensure measurements of weight are precise and dependable in many fields.

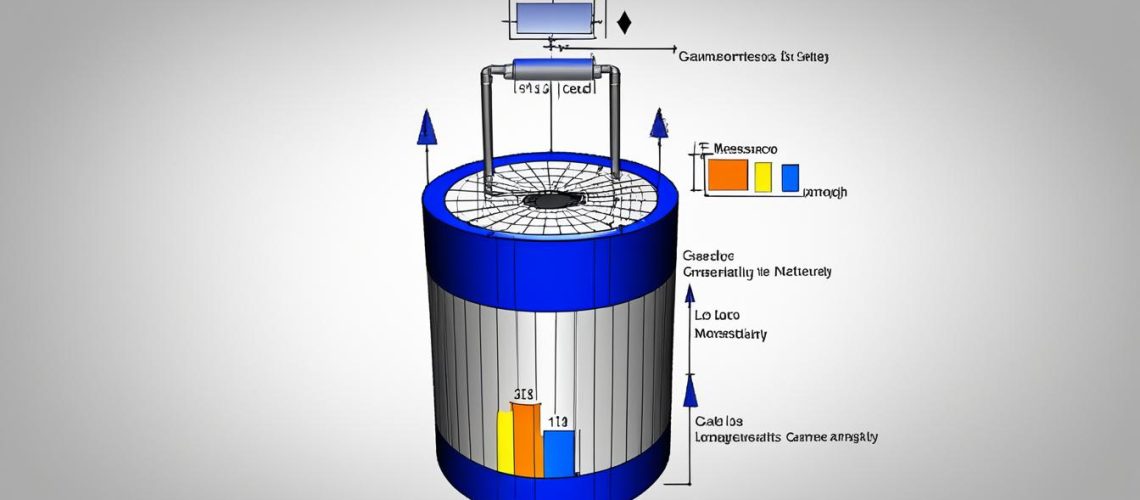

What is a canister load cell?

A canister load cell is a load cell sensor made to withstand tough conditions and heavy loads. It uses strain gauge technology to change force into electric signals. This makes it possible to measure weight accurately in tough places.

Applications of canister load cells

Canister load cells have many uses, especially in transport, building, and farming. They’re vital in weighing trucks, monitoring water levels in tanks, and ensuring safe use of heavy machinery in construction.

The importance of accuracy in load measurement

Getting load measurements right is crucial for safety, efficiency, and quality. Wrong measurements can cause overloads, equipment problems, and risk. So, using a trusted load cell sensor is key for good results in industry.

The Science Behind Load Cell Sensors

Understanding load cell sensors starts with strain gauge technology. This tech is key to measure force accurately.

Understanding Strain Gauge Technology

Strain gauge tech is crucial for load cell sensors. It turns mechanical stress into an electric signal. When under force, strain gauges change resistance. This change shows the stress levels directly.

How Load Cells Measure Force

Load cells measure force accurately by noting tiny deformations. Force changes the strain gauge’s shape and their resistance. The change in resistance matches the force applied.

The Role of Calibration in Accurate Measurements

Calibration is necessary for reliable and precise measurements. It sets the load cell to a known standard. This ensures correct and steady readings. Calibration for measurement precision keeps load cells working accurately, giving dependable results.

| Technical Aspect | Description | Relevance |

|---|---|---|

| Strain Gauge Technology | Converts mechanical stress into an electrical signal through deformation | Enables precise force measurement |

| Force Measurement | Detects changes in deformation to measure applied force accurately | Provides proportional and reliable readings |

| Calibration | Adjusts the load cell to a known standard to ensure accuracy | Maintains measurement precision |

Industrial Weighing Solutions

Canister load cells are crucial for many industrial weighing solutions. They bring big benefits to different fields. Their strong build and accuracy are perfect for tasks needing steady and correct measurements.

Common Industries Using Canister Load Cells

Big industries like mining, logistics, and aerospace use canister load cells a lot. In mining, they help measure what’s been dug up exactly. This makes managing resources easier. Logistical companies use them to weigh big deliveries accurately. This helps distribute loads better and reduces transport damage risk. In aerospace, the cells aid in keeping airplane parts secure and safe.

Case Studies of Successful Implementations

In the logistics world, a top freight company cut down its loading times by using canister load cells. This change was thanks to their weighbridge systems. An aerospace manufacturer also saw big improvements. By using these load cells for testing airplane wings, they got better force measurements. This led to safer planes. These stories show the key part canister load cells play in making industrial weighing solutions work well.

Benefits of Precision Load Monitoring

Adding exact load monitoring to our industrial work brings many pros. It boosts how well we work and makes us more productive. This monitoring lets us check and control how much our machines carry. This means we can run things better and have fewer times when things stop working.

Increased efficiency and productivity

Getting precise data from this kind of monitoring lets us make our work smoother. We make sure our machines do not work too hard, so they last longer. This cuts down on fixing them and we can get more work done. Our work gets done better, and we use our people and machines wisely.

Enhanced safety measures with accurate weighing

Knowing exactly how much our equipment carries makes everything safer. It stops us from overloading, which could be dangerous. Following weight limits keeps us safe and follows the rules. This way, our machines and people are less likely to get hurt.

So, using precise load measuring makes our work better and protect us more. It helps us do our job well while keeping everyone safe.

Choosing the Right High Accuracy Load Cell

To pick the best high accuracy load cell, you must know what your application needs. Each use is different and needs specific attention for the best results.

Factors to Consider

There are a few important things to think about when picking a load cell:

- Load Capacity: Make sure the load cell can carry the maximum weight your application will have, without losing performance.

- Environmental Conditions: Think about the place it will be used, like the temperature, how humid it gets, and if it might be exposed to things that can damage it.

- Dimensions: The load cell’s size and shape must fit where you need to install it.

Key Specifications to Look For

Knowing the specifications of a load cell is key to making a good choice. Look for these important specs when choosing a high accuracy load cell:

| Specification | Description |

|---|---|

| Accuracy | Shows how precisely the load cell can weigh things. More accuracy means more reliable data. |

| Temperature Range | It tells you the temperatures the load cell can work well in without losing performance. |

| Rated Output | Explains the signal the load cell gives depending on the weight on it. A steady signal is key for accurate measurements. |

Canister Load Cell Maintenance Tips

Keeping canister load cells working well and for a long time requires regular care. This care helps prevent surprises that could cause the cells to stop working. It also makes sure they stay useful for a long time.

Regular Inspection and Maintenance

Regular checks are vital for inspection and maintenance of load cells. Looking closely at them often helps us spot any early damage. We check the parts like connectors, cables, and the cell’s body for any problems. This stops big issues from happening and keeps the cells working well.

Common Issues and Troubleshooting

Problems like wrong measurements, inconsistent readings, and slow responses can show up during load cell maintenance. When we troubleshoot load cells, we look for loose wires, make sure they’re calibrated correctly, and check for anything in the air or changes in temperature that might mess with them. Doing maintenance and keeping the load cells within set limits helps solve these problems.

Sticking to these maintenance steps means our canister load cells work reliably. This keeps our weighing work in industries accurate and efficient.

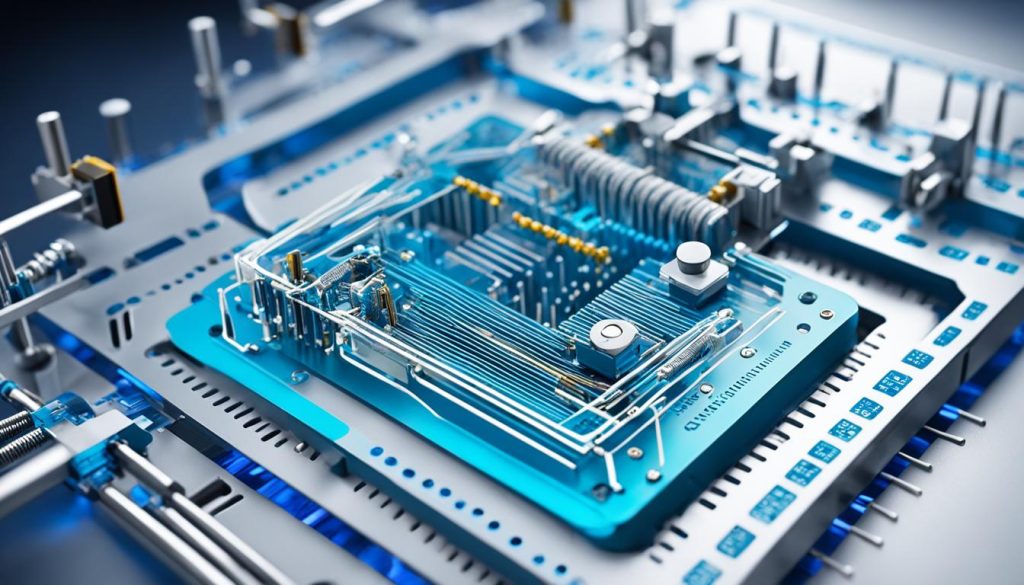

Integration of Compression and Tension Load Cells

When dealing with force measurement, it’s key to know compression and tension load cells. They help you get accurate, reliable readings for your applications.

Differences between Compression and Tension Load Cells

Compression load cells measure forces that press down on them. This is great for calculating weight or pressure. Tension load cells, however, measure forces pulling them, which is ideal for things that hang or pull.

Choosing the Right Type for Your Application

Choosing between compression and tension cells relies on how force works in your project. The kind of force dictates the right load cell. This choice guarantees your system’s correctness and dependability.

| Type of Load Cell | Force Direction | Ideal Applications |

|---|---|---|

| Compression Load Cell | Pushing Forces | Weighing Scales, Hydraulic Cylinders |

| Tension Load Cell | Pulling Forces | Cranes, Suspended Weighing Systems |

The Durability of Canister Load Cells

Canister load cells are known for being very tough. This is because they’re made with strong materials. These materials are carefully chosen to last in tough industrial places. By using the best materials, our load cells work well, even in hard jobs.

Materials used in load cell construction

Our load cells last a long time because we use top materials. We use things like stainless steel and alloy steel. These materials are strong and resist damage well. They help our load cells stay accurate and dependable over time.

How to ensure longevity of your load cells

To make your load cells last, follow good usage and maintenance practices. Always use them as directed. Regularly check them for issues. Catching and fixing problems fast can make them last longer.

By taking good care of your load cells, they will work well for a long time. This combination of great technology and care makes our load cells trusted in many industries. We are committed to offering quality that lasts.