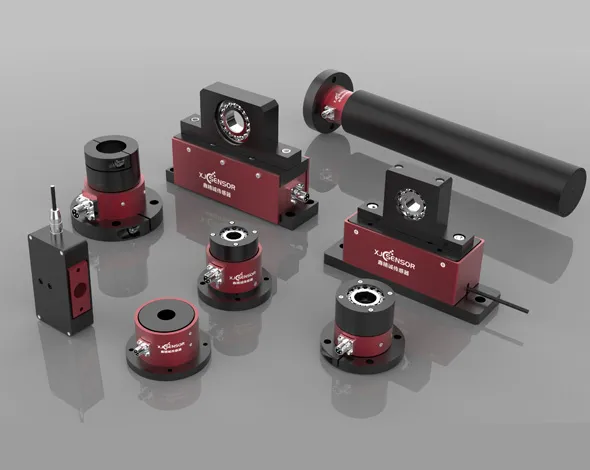

Sensors are changing the automobile industry, leading to innovation and better vehicle performance. They play a key role in modern cars, making them safer and more efficient. Thanks to technology from companies like XJCSENSOR, sensors are now smaller, more dependable, and very sensitive. They deliver precise data and digital output.

Sensors are vital for today’s cars. They monitor systems, providing more control and improving driving. By looking at examples, we see their huge impact on car design. Sensors make cars safer, more efficient, and loaded with new features.

Key Takeaways

- Sensors are critical components in modern vehicle manufacturing.

- Advanced sensors improve operational efficiency and safety.

- XJCSENSOR is at the forefront of sensor innovation in vehicles.

- Automobile sensors ensure control and enhance the driving experience.

- Sensor technology is continuously evolving, offering high sensitivity and reliability.

Introduction to Sensor Technology in Automotive Manufacturing

As the automotive industry advances, the importance of vehicle sensor technology grows. It drives innovation and safety. Understanding how this technology fits into cars shows us the future of car making.

The Rise of Sensor Applications

The journey from basic engine checks to today’s advanced systems shows significant growth. Each step forward has introduced new benefits of using sensors in vehicles. These include better safety, improved car performance, and more reliable driver assistance.

Modern cars have many sensors working together to give real-time data. This improves how decisions are made and increases how well everything operates. The auto industry has seen a boom in sensor use. This is because of strict safety rules and people wanting smarter cars.

Overview of Sensor Types

Sensors in cars come in many types, each designed for a specific task. Let’s look at some main categories:

- Temperature sensors: They keep tabs on the engine’s heat, ensuring cars run well without overheating.

- Pressure sensors: Important for tire and fuel systems, these sensors help cars run efficiently.

- Motion detectors: Essential for safety features like ABS and ADAS, improving safety and control.

Understanding and using these automotive sensor types allows car makers to innovate. Leveraging this tech, we’ve seen big improvements in how cars work and keep us safe.

In conclusion, advanced sensor technology has transformed car making. As we find more uses for sensors, their benefits in vehicles become clearer. This is leading to safer and more efficient cars.

Automotive Electronic Test Button Click Force

Determining how much force is needed to press electronic buttons in cars matters a lot. It makes sure cars are easy and nice to use. Sensor technology plays a big part in this.

Groups like XJCSENSOR lead the way in making this process better. They use new tech for more precise tests. This helps car makers know how long car parts last and if they are good enough.

Adding advanced weighing systems to cars helps too. It lets car makers see how forces impact a car’s performance. This is key when you think about how often you click these buttons. They need to keep working after lots and lots of clicks.

Using smart sensors in tests makes sure car parts can be trusted for a long time. Keeping track of click force data helps in picking the right materials and designs. This leads to a smoother experience for users.

To wrap up, measuring button click force in cars is key. It helps in keeping cars working well and lasting long, thanks to the latest in sensor tech. As car technology evolves, these sensors will help make sure cars remain top-notch in quality and dependability.

Tests for Plug and Pull Force of Connector

Testing each connector is key to a car’s electrical system integrity. Such tests are essential for the automotive components’ performance and life span. A test for plug and pull force of connector helps stop failures and keeps the quality needed in the automotive world.

Importance of Connector Testing

Connector testing is vital, notably for the role of sensors in automobile safety. Connectors serve as crucial points in a car’s electrical system. Failure here can cause big problems, like electrical shorts. Making sure connectors can handle regular use forces is key to a car’s reliability and safety.

How Sensors Enhance Connector Reliability

Thanks to sensor technology for automotive industry, connector testing has improved. Modern sensors give precise data on connector strength and durability. This lets manufacturers make stronger connectors, ready for real-world use. Sensors help ensure connectors meet standards, boosting a car’s reliability and safety.

| Testing Parameter | Traditional Method | Sensor-Based Method |

|---|---|---|

| Measurement Accuracy | Moderate | High |

| Data Collection | Manual | Automatic |

| Failure Detection | Human-Dependent | Real-Time Alerts |

Crash Test and Safety Innovations

In modern car making, crash tests are crucial for ensuring vehicle safety. They use automobile sensors to collect crash data. This helps make cars safer using sensor tech.

Automobile sensors have changed how we see car safety. These sensors give real-time data. This helps airbags and safety systems work right away in a crash. It makes it much safer for everyone in the car, showing how vital sensors are in crash tests.

One big step in safety is the progress in safety measures with sensor technology. These methods don’t just react; they also prevent accidents. Below are some main sensor-based safety features used in crash tests:

| Safety Feature | Description | Role of Sensors |

|---|---|---|

| Airbag Deployment | Protects occupants during a crash | Sensors detect collision force and speed |

| Seatbelt Pre-tensioners | Tighten seatbelts before impact | Sensors predict collision likelihood |

| Automatic Emergency Braking | Applies brakes to prevent collisions | Sensors monitor distance to obstacles |

| Collision Avoidance Systems | Warns drivers of potential hazards | Sensors track vehicle surroundings |

Car companies keep innovating with every crash test. By using top automobile sensors, they’re making cars much safer. This means we can feel more secure on the road than ever.

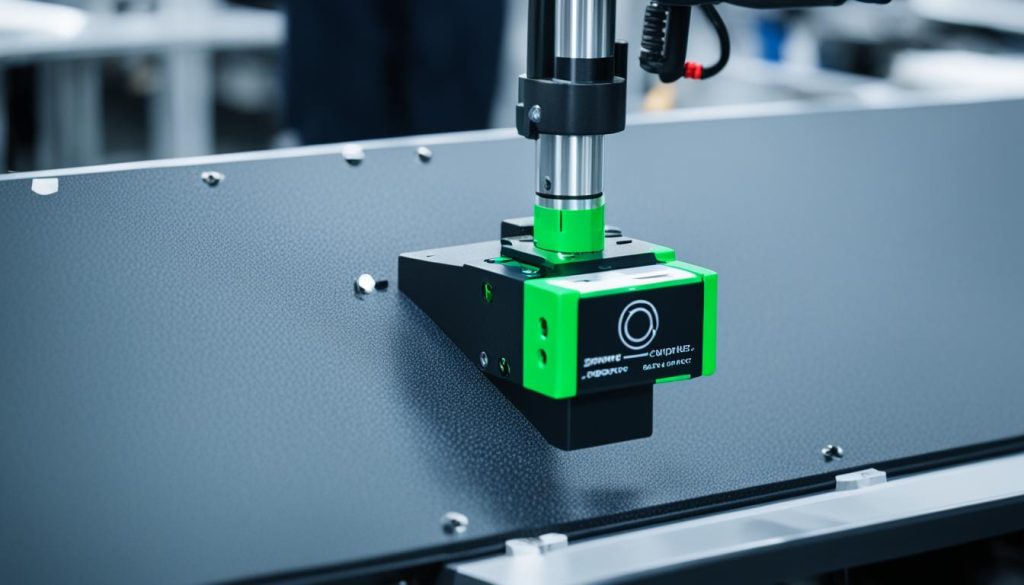

Dimensional Measurement of Automotive Parts

Precision in measuring automotive parts is key for safety and top performance. Today’s sensors in cars help make this happen. They let manufacturers be more accurate than ever in making cars.

Ensuring Precision in Manufacturing

The path to precision starts with the latest sensors on the production line. These sensors check every part’s size to meet strict standards. This makes sure every part fits perfectly in the car, reducing mistakes.

Role of Sensors in Dimensional Accuracy

Advanced sensors in cars improve accuracy. They find small errors, keeping the car’s quality and safety high. These sensors also make manufacturing flexible, adjusting to keep things consistent and high-quality.

- High-resolution sensors for detecting minimal variances

- Real-time data analysis for immediate adjustments

- Enhanced repeatability and reliability in measurements

Advanced sensors are pushing the auto industry forward. They guarantee each part meets the standards needed for modern cars. This shows the industry’s dedication to quality and safety.

Performance and Fatigue Life Test of Various Parts of Automobiles

Testing the performance and fatigue life of automobile parts is key for vehicle reliability. These tests check if automotive components can last long under stress. They use sensors to get precise data on part durability.

Monitoring Part Durability

To learn how car parts handle stress, we monitor them closely. Advanced sensors help us collect detailed data on automotive assembly under force. This lets us forecast which parts might fail, ensuring they’re both tough and dependable throughout the car’s life.

Advantages of Sensor-Based Testing

Sensor integration in testing automobile parts has many benefits. It increases accuracy and provides real-time data. This removes the guesswork, allowing engineers to improve component designs better. Sensor testing helps make manufacturing more efficient, saving time and resources while upholding safety and quality.

| Test Type | Description | Benefits |

|---|---|---|

| Performance Test | Evaluates the functionality of automotive parts under various conditions. | Ensures parts meet operational standards and improve overall vehicle performance. |

| Fatigue Life Test | Assesses the endurance of components by subjecting them to repeated stress cycles. | Predicts potential failures and extends the lifespan of parts. |

| Sensor-Based Test | Utilizes sensors to monitor and record real-time data on part performance. | Provides accurate, actionable insights that enhance design and manufacturing processes. |

With sensor-based testing, we make cars more durable, reliable, and efficient. As the auto industry embraces this technology, we get closer to making precision and quality key features of car assembly.

Automotive Assembly Over Force and Quality Control

Car manufacturing is complex and demands precise force. This ensures every part fits just right without harm. The role of sensors in automobile safety is crucial here. They keep a keen eye on automotive assembly over force events. This helps prevent damage that could easily be missed.

Sensors do more than stop too much force. They boost the quality control in car manufacturing. They review data non-stop, providing quick feedback. This process makes sure every step meets high industry standards. By adding sensors, we see how new tech pushes the car industry ahead. This lets manufacturers make cars that are safer and better quality.

Thinking about this technology’s impact? Here’s what it brings to the table:

- Consistency: Sensors apply force evenly across all parts.

- Accuracy: They find issues before they cause big problems.

- Efficiency: They cut down on the need for people to check things.

These sensors tackle automotive assembly over force risks head-on. They are vital for keeping quality control in car manufacturing high. As cars and tech grow together, improving sensor tech will surely make cars safer and more reliable.

Automobile Welding Force Detection Techniques

Welding holds cars together and requires the right amount of force. Sensor technology helps us monitor this force, improving safety and product quality.

Maintaining Welding Integrity

It’s crucial to detect welding force accurately in cars. Sophisticated sensors measure this force during welding. This ensures welds are strong and cars last longer.

Safety Measures with Sensor Technology

Using sensors for cars does more than boost performance; it’s key for safety. These sensors catch any welding errors quickly. This allows for rapid fixes, keeping the welding excellent.

Sensors make sure the car’s structure is secure. They stop weaknesses that could cause breakdowns.

Here’s how sensors help keep welding top-notch:

- Precision: They detect and adjust welding force accurately.

- Quality Control: They watch the welding non-stop and fix issues right away.

- Safety: They help cars be durable and avoid structural flaws.

Car Riveting Assembly and Structural Strength

In car riveting assembly, precision means everything. Now, sensors in cars have changed the game. Every rivet strengthens the car thanks to these sensors. They check the force during riveting. This lets us adjust on the fly to keep up quality.

Sensors improve accuracy in making cars today. They find the perfect pressure for each rivet. This avoids making them too tight or not tight enough. Getting it just right is key for a car’s strength. This strength affects safety and how long the car will last.

Here’s something cool – sensor data makes assembling cars better. It speeds up the process, without cutting corners on safety. With advanced sensors, we’re making strides toward safer, more dependable cars. This is a big win in making vehicles today.

Conclusion

The world of car making is changing fast because of new sensor tech. These sensors help make cars safer and the making of cars smoother. This is not just about new tech. It’s about making cars that are better for everyone.

Sensors are key in the car industry. They help with accurate measurements and keeping quality high. They are vital for making cars we can rely on. Sensors are especially important for safety. They help with things like knowing when to open airbags and checking if the car’s structure is strong.

Companies like XJCSENSOR are leading the way with this tech. They show us what sensor technology can do now and what it might do in the future. The future looks bright. Sensor tech will keep playing a big part in making cars that are smart, safe, and efficient.