Do you ever think about what keeps critical industrial work running smoothly? Precision load cells are essential for accurate force measurement in important operations. They turn force into electrical signals with precise reliability. These devices are crucial in fields needing perfect accuracy.

Precision load cells are key for quality control, safety, and research. They handle both moving and still weights with the latest tech for exact measurements. This precision is priceless in industries where being absolutely precise is a must.

Key Takeaways

- Precision load cells are crucial for accurate force measurements in high-stakes applications.

- These devices convert force into electrical signals, ensuring precise readings.

- They facilitate quality control, ensure safety, and support research and development.

- State-of-the-art precision weighing technology caters to both dynamic and static tasks.

- Indispensable in sectors demanding unwavering accuracy.

Introduction to Precision Load Cells

Precision load cells are key parts in many fields, ensuring exact measurements. They change mechanical force to electronic data with great accuracy. This data is vital for various uses.

What are Precision Load Cells?

These cells are very accurate sensors. They measure the force or load precisely. They turn this mechanical force into electronic signals.

This lets us know the exact weight or force. They are crucial in engineering and science for accurate readings every time.

Importance of Accuracy in Weighing Solutions

Being accurate in weighing things is very important. It means products are good, machines work well, and safety rules are followed. Sensors that are extremely precise are essential for this.

They provide reliable data for important decisions. When load cells are right, they stop machines from breaking and keep things running smoothly. This is critical in serious settings.

The Science Behind High Precision Sensors

High precision sensors are key in advanced load cell tech. They spot tiny changes when a load is put on. Equipped with strain gauges, these sensors change mechanical forces into precise signals.

How High Precision Sensors Work

Strain gauges play a major role in high precision sensors. They are attached to the sensor. When a load is applied, they change shape, altering electrical resistance. This change is then turned into a signal that shows the force applied. This makes the precision load sensor very accurate for different industries.

Technology Advancements in Load Cells

Recent advancements in load cell technology have made these sensors better. They are now more durable in tough conditions. They also have improved signal processing, making them more sensitive and accurate. This means they can spot even the tiniest forces and measure them right.

This progress has also led to smaller, better sensors. These improvements increase their use in precise manufacturing and engineering. Precision load sensors can now meet the growing needs of various industries, thanks to these advances.

Benefits of Using a Precision Load Cell

Using a precision load cell is key in many industries. These sensors provide very accurate force measurements. This gives us reliable results across different uses.

Precision load cells are known for their exceptional accuracy. They are used in robotics, haptics, and medical tools. Their precise force readings ensure things work well. Load cells are made of top-notch materials like steel or aluminum. This makes them strong in many settings.

The design of load cells keeps getting better. They now have features that protect them, like epoxy filling. Such designs last longer, and certifications make them safe in any condition.

Using load cells can actually save a company money. Because they’re so accurate, they cut down on waste and make things safer. This helps products last longer and work better. But, remember – they must be installed and calibrated correctly to work best.

To sum up, precision load cells boost how well things run. They offer top-notch accuracy and reliability. This is critical for keeping high standards in different fields.

Types of Precision Load Cells

Learning about the various kinds of precision load cells is key to picking the right one for your use. Each one works in a different way to measure weight precisely. This makes them fit for various needs in industries.

Strain Gauge Load Cells

A strain gauge load cell stands out for its precision and how it can be used in many ways. It works by putting strain gauges on the object that feels the force. So, when force is used, the strain gauges see the object change slightly. Then they turn this tiny change into an electric signal.

Capacitive Load Cells

Capacitive load cells have a special way to notice changes in capacitance that show the force applied. They are super sensitive and can give really clear measurements. This makes them great for uses needing to notice very small changes in force.

Piezoelectric Load Cells

Piezoelectric load cells work differently, using the piezoelectric effect. They are perfect for measuring forces that change quickly. For example, they are often used in places that do dynamic tests.

Applications of Accurate Load Cells in Various Industries

Accurate load cells are essential in many fields. They bring better precision and efficiency. Their use improves industrial weighing accuracy and betters processes in various areas.

Manufacturing

In manufacturing, load cells play a key role in automation and quality control. They’re critical for maintaining industrial weighing accuracy. This helps keep things consistent and flawless, improving how things are made.

Healthcare

Healthcare heavily depends on precise load cells for scales and monitoring. These tools give exact measurements for diagnosis and care. They ensure our health systems get industrial weighing accuracy for the best care and new findings.

Agriculture

In farming, load cells optimize how we harvest crops and handle supplies. They boost efficiency and make things run smoothly in agriculture. Their use manages crops better and uses resources wisely, making a big difference.

| Industry | Key Benefits | Examples |

|---|---|---|

| Manufacturing | Automation, Quality Control | Assembly Lines, Packaging |

| Healthcare | Precision, Reliability | Patient Monitoring, Laboratory Scales |

| Agriculture | Efficiency, Resource Management | Harvesting Equipment, Feedstock Management |

Ensuring Load Cell Accuracy

Keeping load cells accurate is crucial. It means our measurements are reliable, helping everything run smoothly. Regular calibration and maintenance are key to keep these devices at their best.

Calibration Procedures

Getting calibration right is how we keep our load cells precise. We need to follow a set method. This ensures our devices are giving us the correct info:

- Make sure your load cell is clear and straight.

- Use special weights to check if the load cell is right.

- Write down the numbers and set it to be correct if needed.

- Do a few tests to be sure it works the same every time.

When we calibrate carefully, the readings we get are correct. This helps with making sure things are up to standard and safe.

Maintenance Tips

Looking after load cells well makes them last and stay right. Here are tips on how to do this:

- Regular Inspection: Check your load cells often for any issues. Fixes should happen fast.

- Cleaning: Use the right methods to clean cells. This stops bad stuff from building up and messing with readings.

- Recalibration: Keep a schedule to check and adjust if needed. This is extra important after a big use.

- Environmental Control: Keep cells in a safe place, away from bad weather and too much movement. This protects their accuracy.

By following these tips, you avoid problems and keep your measurements reliable.

Importance of Load Cell Calibration

Calibration importance is key in precision weighing systems. It keeps measurement accuracy high. Calibration corrects deviations. This ensures consistent and reliable results that meet regulations and quality standards.

Why Calibration is Crucial

Calibration for precision weighing is critical. Load cells face many challenges that impact their performance. These include zero offset, linearity issues, hysteresis, and repeatability. Such issues can affect the accuracy and consistency of weighing results.

Regular calibration addresses these issues. It keeps load cells working well and producing accurate results.

Step-by-Step Calibration Guide

Following a detailed calibration process is essential. It ensures load cells meet the necessary standards. Here’s a guide for successful precision weighing calibration:

- Initial Inspection: Check for physical damage or contamination.

- Zero Calibration: One-point calibration fixes zero offset error, making measurements accurate even at zero load.

- Span Calibration: Use two-point calibration to fix sensor offset at two values. This makes measurements accurate across the scale.

- Multi-Point Calibration: For very accurate results, do a five-point calibration across different percentages of the measurement range.

- System Calibration: Combine sensor and instrument calibration for system-wide accuracy.

| Calibration Type | Procedure | Accuracy Level |

|---|---|---|

| Zero Offset | Adjust at zero load | Ensures baseline accuracy |

| Two-Point | Adjust at two output values | Creates linear accuracy |

| Five-Point | Adjust at multiple percentages of sensor range | Provides high precision |

| System Calibration | Combines sensor and instrument calibration | Enhances overall system accuracy |

For strain gauge load cells, FUTEK suggests yearly recalibration. This is especially important in critical or tough environments. By calibrating regularly, we ensure precise and reliable measurements. This is crucial in industry and science.

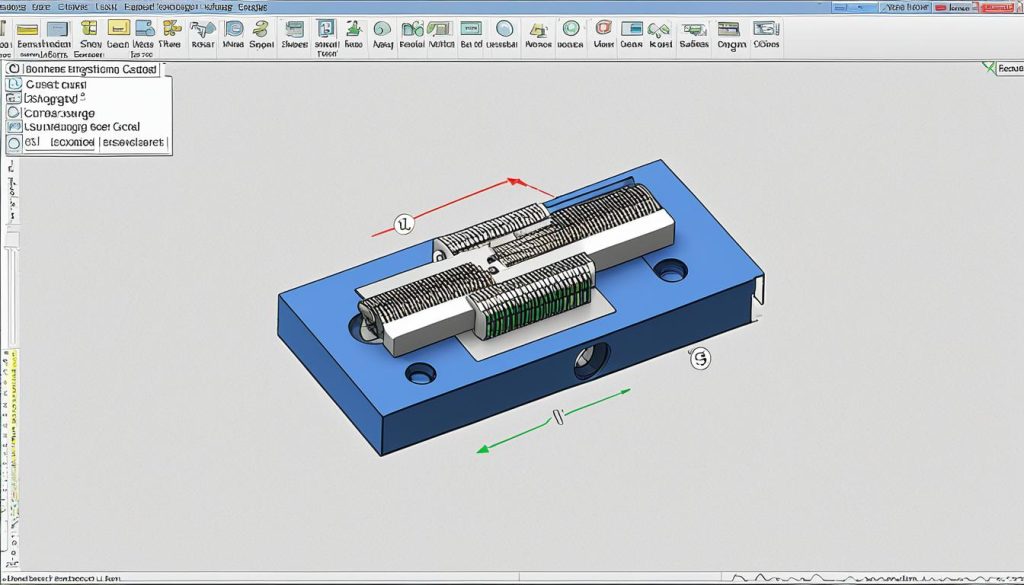

Precision Force Measurement Techniques

Getting force measurement right means using advanced methods. These methods help precision load cells work well. They make sure our measurements are correct and reliable.

- Proper Alignment: Using the right fixtures ensures everything is set up correctly. This is key for accurate force measurement. Wrong alignment causes mistakes in our data, so precision is crucial.

- Settling Time: Giving enough time for everything to settle reduces errors. This step makes sure our readings are steady and correct. It’s a big part of being accurate.

- Environmental Compensation: Special software can handle changes like different temperatures and levels of humidity. This keeps our measurements consistently precise.

By using these advanced methods, our weighing systems become very accurate and reliable. Focusing on proper alignment, enough settling time, and adjusting for the environment. These steps ensure our measurements are always true and dependable.

How to Choose the Right Precision Load Cell

Choosing the best load cell involves many important factors. To get the best results, the right load cell must be picked. This ensures accurate and trustworthy weight measurements.

Factors to Consider

When choosing a load cell, several key points are critical to remember:

- Load Capacity: Knowing the biggest weight the load cell will measure is crucial. It needs to handle this without losing accuracy.

- Size Restrictions: The load cell must fit your equipment’s space. So, check its physical size carefully.

- Environmental Conditions: Think about where the load cell will be. Factors like temperature and moisture can affect its performance.

- Accuracy Requirements: The level of precision needed varies by use. Ensure the load cell you pick is accurate enough for your needs.

Comparing Different Load Cells

After noting these essential points, compare various load cells. We need to match different load cells to our criteria. This method helps us find the best one for our needs.

| Load Cell Model | Load Capacity | Size | Environmental Suitability | Accuracy Level |

|---|---|---|---|---|

| Model A | 500 kg | Compact | High humidity tolerance | ±0.02% |

| Model B | 200 kg | Slim profile | Temperature resistant | ±0.05% |

| Model C | 1000 kg | Standard size | Corrosion-resistant | ±0.01% |

By carefully comparing different load cells, we ensure our choice fits our exact needs. This guarantees our weighing systems perform accurately and precisely.

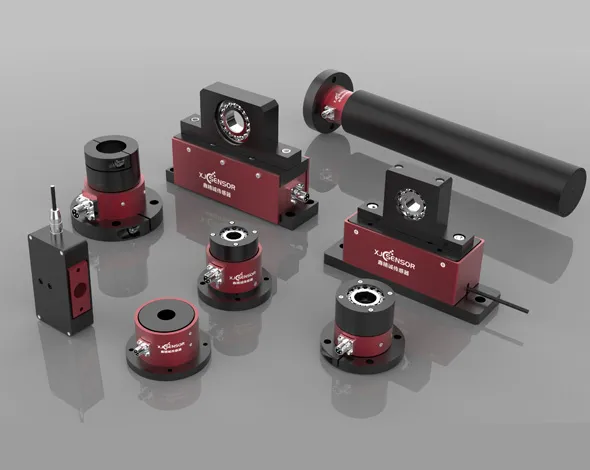

XJCSENSOR: Leading Provider of Precision Load Cells

XJCSENSOR excels in making accurate and innovative precision load cells. We combine advanced technology with high-quality materials. This ensures our products meet the tough demands of many industries. We’re dedicated to providing the best solutions for measuring forces precisely.

Our Products

Our range of precision load cells at XJCSENSOR meets unique customer needs. We offer various types, including:

- Strain Gauge Load Cells – These are great for many jobs because of their accuracy and flexibility.

- Capacitive Load Cells – They use changes in capacitance to measure force. They’re perfect for exact and dependable measurements.

- Piezoelectric Load Cells – Perfect for dynamic force measuring, as they use the piezoelectric effect.

We’re committed to innovation and excellence for every product we offer. They’re designed to perform exceptionally well in any situation.

Client Testimonials

At XJCSENSOR, customer satisfaction is key. Here is what our customers say:

“The precision load cells from XJCSENSOR have significantly improved our quality control processes. Their accuracy and reliability are unmatched.”

“XJCSENSOR’s customer service is outstanding. Their expertise and dedication to client satisfaction make them our go-to provider for precision load cells.”

These quotes show our dedication to excel and make our customers happy. They help establish us as a trusted industry leader.

Conclusion

The market for precision load cells is growing fast. We need them to be more accurate and reliable in many areas. This keeps our weighing solutions up-to-date. They are vital from making things to taking care of health and crops.

Our commitment is to keep improving these products. We use new technologies and focus on quality. This makes sure our load cells give exact and dependable results for many uses. Our goal is to exceed today’s high standards for precise force measurement.

The future of precise weighing looks promising. It’s driven by the growing importance of precise data. We will keep working on load cell technology. This will lead to even better, dependable, and precise weighing solutions. Our aim is to meet the changing needs of industries and customers. Let’s move forward together towards more precision and reliability in measuring force.