How does something so tiny provide such exact weight results?

Micro load cells offer a significant breakthrough in precision measurement of weight and force. They are known for being small, tough, and very accurate. This makes them ideal for use in places like medical equipment, robots, and the aerospace industry. They meet the strict demands for weight measurements in these areas.

Their small size doesn’t mean they are less accurate. These sensors can provide precise and reliable weight readings. This sets them apart from other weighing methods. Let’s look at the technology that makes micro load cells so good for getting exact measurements.

Key Takeaways

- Micro load cells offer high-precision weighing capabilities in compact form factors.

- These sensors are crucial in industries where accurate measurements are critical, such as medical devices and aerospace engineering.

- Their durability and reliability make them a preferred choice for both industrial and consumer applications.

- Micro load cells excel in spaces where traditional sensors may not fit, without sacrificing performance.

- Advancements in micro load cell technology continue to enhance their effectiveness and applicability.

Introduction to Micro Load Cells

Micro load cells are key in many areas because they’re small, precise, and efficient. They stand out in the sensor world for some solid reasons. We’re going to talk about why they’re top choice and how they’re used.

Why Choose Micro Load Cells?

One big reason people love micro load cells is their accurate results in a tiny size. They can handle big loads despite their smallness. This fact is perfect for places with limited room. Their quick response means you get exact data right away, which is very important in fast-moving settings.

Adding a good load sensor to any system ups its accuracy and efficiency. Micro load cells are tough, working well even in rough conditions. Their use in fields like medicine and space shows they offer steady, reliable weight readings.

Applications of Micro Load Cells

Micro load cells are used in a wide range of fields. They better control and watch over making things in factories. In medicine, they help measure medicine and make it just right. They’re vital in precise work, finding even tiny changes in weight.

Their force transducer jobs see them in robots, helping make them smarter and quicker. They’re key in making autos safe, checking the force each part handles. Overall, micro load cells do a lot, aiding many sectors with their great service and trustworthiness.

Understanding Load Sensors and Their Functionality

Load sensors are key in getting accurate weight measurements in many fields. They act to tell how much weight is on them by turning it into an electric signal. This electric signal gives us exact weight figures needed for many uses.

Load sensors work with special parts like strain gauges to work. Strain gauges change their resistance when they bend with weight. This resistance change represents the weight placed on the sensor. So, we get precise weights for different needs.

Load sensors are vital for getting exact and stable weight figures. They are used everywhere, from factories to hospitals to make sure things weigh right. Their job is very important in many fields.

Here’s how load sensors work, with a quick look at the parts and what each does:

| Component | Function |

|---|---|

| Strain Gauge | Detects deformation and converts it into electrical signals |

| Sensing Element | Receives the load and transfers stress to the strain gauge |

| Bridge Circuit | Converts the finite changes in resistance for precise readings |

| Output Device | Displays or records the measured load data |

In conclusion, knowing how load sensors work and their role is crucial. They are the base for accurate weight measurements in critical settings.

The Role of Force Transducers in Precision Weighing

Force transducers are key in precision weighing. They turn physical force into measurable electrical signals. These high-tech tools ensure weight is measured accurately in many fields, from industry to space.

How Force Transducers Work

A vital part of a force transducer is the strain gauge. It senses any shape change caused by a force and turns it into an electrical sign. When the force changes the gauge’s shape, it changes the electrical resistance. This change gives us a clear electrical output showing the applied force. This system is very accurate and repeatable, crucial for weighing things exactly.

Types of Force Transducers

There are many kinds of force transducers, each for specific uses:

- Hydraulic force transducers: They measure force by using fluid pressure changes. They are good for heavy-duty work.

- Pneumatic force transducers: These use air pressure. They are great where there should be no electronic interference.

- Piezoelectric force transducers: They use materials that create an electric charge under force. They work well for quick, changing forces.

FUTEK makes force transducers with aerospace-grade materials like stainless steel and aluminum. They are known for their super exact load cells, with errors as low as ±0.02%. They are praised for being very reliable over time, having different sensor shapes, and being very precise. This makes them a top choice in exact weighing.

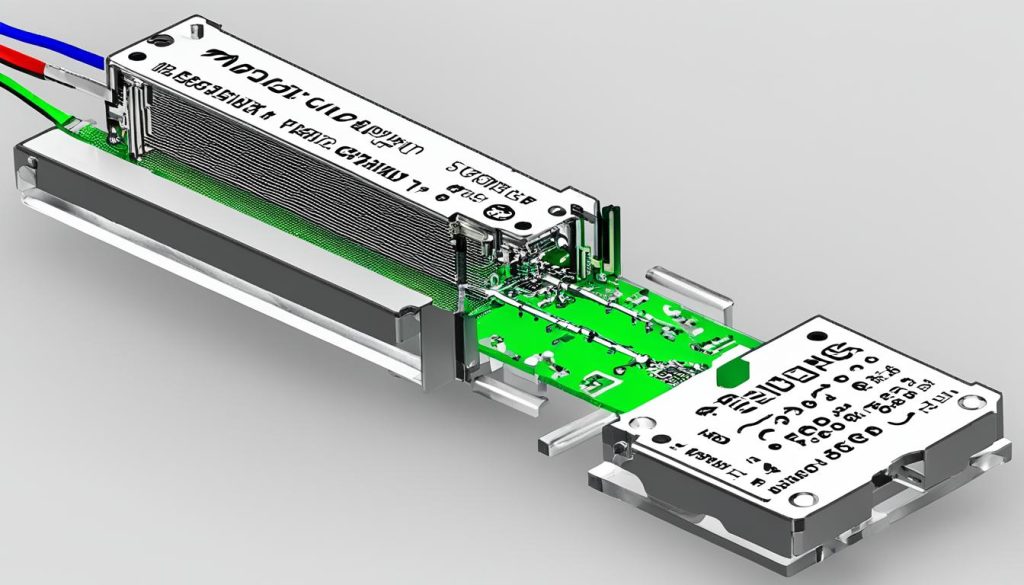

Strain Gauge Technology in Micro Load Cells

Strain gauge technology makes micro load cells work well in small spaces. It gives high precision and strength at the same time. This is because of the sensors based on strain gauges.

Key Components of Strain Gauges

Strain gauges have key parts, with the resistive material being vital. This material changes resistance under force, showing how much the load cell gets stressed. Also, coatings and base materials help these sensors work longer.

Advantages of Strain Gauge-Based Sensors

Strain gauge sensors offer many advantages. They are very sensitive, helping in tasks where being exact is crucial. They also use little power, fitting well in gadgets with not much power.

Plus, they are cost-effective, which makes them a top choice in many fields. This is why these sensors are trusted in many load-bearing uses for their consistent results.

Comparing Weight Sensors: Micro Load Cells vs. Traditional Load Cells

Comparing small-scale load cells with old-style ones shows clear differences in benefits. Knowing these differences helps pick the best one for each use.

Let’s start with size. Small-scale load cells are much tinier than traditional ones. They fit well in small spaces. Even though they’re small, they’re just as strong and sensitive. Modern tech has made sure they are as accurate and reliable as bigger options.

Now, let’s look at how much weight they can handle. Traditional load cells can take on heavier weights, great for big industrial jobs. But, small-scale load cells work better for lighter weights that need high precision, like in medicine or with tiny robots.

Sensitivity is also key. Small-scale load cells are more sensitive because of how they are made. This makes them perfect for jobs needing very accurate weight measures. Yet, traditional load cells are better for big, not-so-precise measurements you might find in industry.

| Feature | Small-Scale Load Cells | Traditional Load Cells |

|---|---|---|

| Size | Compact | Bulkier |

| Capacity | Low to Medium | High |

| Sensitivity | High | Moderate |

| Application | Medical, Robotics | Industrial, Heavy-Duty |

Choosing between small-scale and traditional load cells depends on the job. Thanks to new tech, even the small ones are accurate and do their job well. Knowing what each type is good at helps us pick the right one for our needs.

Why Choose a Compression Sensor for Specific Applications

Compression sensors are often the best pick for industry needs. They provide top-notch accuracy and consistency. This is crucial for places that must have reliable force measurements.

Benefits of Compression Sensors

These sensors shine by staying accurate even when temperatures change. They are also very strong and last long. This means lower upkeep costs and a sensor that serves you for a long time.

- High repeatability under varying conditions

- Reduced sensitivity to extreme temperatures

- Durable and reliable performance over time

Common Uses of Compression Sensors

Compression sensors have key roles in many areas. For example, in bolt fastening they ensure the right torque, avoiding issues like over-tightened bolts. They’re crucial in industrial scales too, for spot-on load measurements over big ranges.

Also, in checking buildings and bridges for safety, these sensors shine. They accurately measure stress and strain. This helps ensure the structures are sound.

Compression sensors enhance precision and reliability in various industries. They are a key part of advanced measuring tools today.

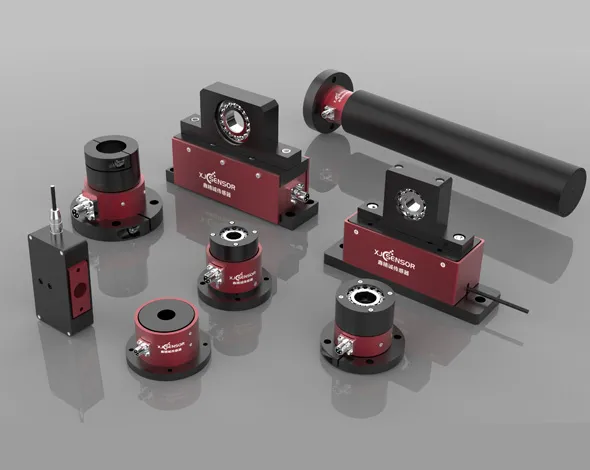

XJCSENSOR’s Range of Miniature Load Cells

At XJCSENSOR, we offer a wide selection of miniature load cells. They are perfect for precise weighing in many areas. We focus on making our sensors top-notch in performance, accuracy, and reliability, even in tough conditions.

Our load cells are great for many uses, from industry to medicine to space. They are built to be very sensitive, quick, and long-lasting. With such qualities, they’re highly respected in their field.

Choosing XJCSENSOR means getting solutions just right for you. We know every customer is different. So, we can adjust our load cells to your needs. This shows our commitment to making sure our products work perfectly for you.

Let’s highlight some top products and their unique features. They’re great for a variety of sectors:

| Product | Capacity Range | Accuracy | Applications |

|---|---|---|---|

| Model XYZ-1 | 0-500g | ±0.05% | Medical Devices, Robotics |

| Model XYZ-2 | 0-2000g | ±0.02% | Industrial Automation, Aerospace |

| Model XYZ-3 | 0-5000g | ±0.01% | Precision Instruments, Material Testing |

Our range of products suits many precision weighing needs. XJCSENSOR stands out by using the latest tech and creative designs. We’re committed to offering the best miniature load cell solutions.

The Importance of Micro Weighing Cells in Modern Technology

Today, micro weighing cells are key in our tech world. They are known for their precise measurements and wide use. These devices help us measure things accurately in many areas. This is vital in industries and for regular people too.

Innovations in Micro Weighing Technology

The latest in micro weighing tech uses new materials and smarter electronics. They are now smaller, but more sensitive, thanks to silicon sensors. Also, they can transmit data without wires. This makes them more useful in healthcare, robots, and space tech.

Future Trends in Micro Weighing Cells

The future of micro weighing cells looks bright. They will soon work with the IoT. This will make them smarter and more connected. Plus, new materials will make them tougher and tinier. Keeping up with these trends will help our tech stay the best.

Advantages of Using Small-Scale Load Cells

Thinking about precision weighing? Small-scale load cells offer huge benefits. Their small size fits easily into existing setups. This is perfect for places where saving space is key.

They are very accurate and reliable too. Built tough, they can handle tough places. So, they work well in many industries and for research.

It’s also easy to add them to different systems. This makes everything more simple and running smoothly.

| Feature | Small-Scale Load Cells | Traditional Load Cells |

|---|---|---|

| Size | Compact | Larger |

| Integration | Easy | More complex |

| Accuracy | High | Moderate |

| Durability | Robust | Standard |

Small-scale load cells are great for precision weighing. They are compact, easy to add, very accurate, and strong. These features show their value in various fields, from making things in factories to advanced research.

Compact Force Sensors: A Detailed Overview

In applications where precision is key, compact force sensors play a major role. They’re crucial in tight spaces. Even though they’re small, they deliver top-notch performance. This makes them vital in many industries. We will look into what makes them tick and how to pick the right ones.

Design and Structure of Compact Force Sensors

The design and structure of these sensors mix small size with big performance. They use precise materials to be both tough and sensitive. A process called microfabrication helps keep them small but highly effective. Components like microelectromechanical systems (MEMS) make them light yet strong.

Performance Metrics to Consider

Several performance metrics matter for a compact force sensor:

- Sensitivity: It is key for catching even the tiniest force changes.

- Resolution: This is about the smallest force the sensor can pick up. It’s important for very detailed work.

- Operating Temperature Range: The sensor must work well in the application’s temperature. This is needed for reliable measurements in any setting.

Here’s a quick look at crucial performance metrics for choosing the best compact force sensor:

| Performance Metric | Description | Importance |

|---|---|---|

| Sensitivity | How well the sensor notices force changes | High |

| Resolution | The least amount of force the sensor can measure | High |

| Operating Temperature Range | The temperature range the sensor works well in | Moderate to High |

Knowing about these metrics can guide your choice in incorporating compact force sensors into systems. This helps meet the exact needs of any job.

Micro Load Cell: Precision Weighing Sensors for Accurate Measurements

Precise weight measurements need the right tools. Micro load cells lead in this area, giving high-precision answers for many uses. They are small, sturdy sensors that change how we measure weight and force. They catch even the tiniest differences with accuracy.

Micro load cells shine in fields like medical devices, robots, and aerospace. They do well in tight spaces, keeping up high accuracy. They help keep a check on robotic arms and measure medicines exactly.

What makes micro load cells special is their top-class features and strength. They can work in tough places while staying sensitive. They change tiny changes in force into clear data, a key part of today’s industries.

Connecting micro load cells to other tech is easy because of their design. This opens new ways for engineers and scientists to use them. As we need more precision, micro load cells show us the future in measuring, setting high new standards.

Conclusion

After exploring what micro load cell technology offers, it’s easy to see their importance. These small but precise devices are key in many industries. They bring a level of accuracy and reliability that was not possible before.

Their impact is big, from helping in medical fields to space exploration. Companies like XJCSENSOR lead the way in innovation, making high-quality micro load cells. This helps industries work better and more accurately.

In the future, micro load cells will become even more important. They will be a major part of new, smart systems and technologies. As technology advances, so will the role of micro load cells. They will continue to be essential for getting reliable measurements.