Micro force sensors play a vital role in many fields like robotics, healthcare, and cars. They offer accuracy in force measurements. And this allows for precise control and data gathering in tough settings. XJCSENSOR leads the way in making these sensors, offering a wide array of solutions for various industries.

Key Takeaways

- Micro force sensors are essential for precise force measurement in a variety of industries.

- XJCSENSOR is a leading provider of micro force sensor solutions.

- Accurate force data is critical for enabling advancements in robotics, automation, and medical devices.

- Micro force sensors offer exceptional precision, compact design, and versatile applications.

- XJCSENSOR’s expertise in micro force sensor technology helps drive innovation across multiple sectors.

Understanding Micro Force Sensors

Micro force sensors are designed for measuring small forces with high accuracy. They are key in areas like robotics, medical devices, and research. They help in fields like tactile sensing and strain analysis.

These devices measure forces as small as a few micro-Newtons. They use advanced technologies to be very sensitive and accurate. This allows them to track tiny force changes crucial for many uses.

What are Micro Force Sensors?

Micro force sensors are devices that can measure forces in the micro-Newton (μN) or even nano-Newton (nN) range. These sensors leverage advanced technologies, such as capacitive, piezoresistive, and MEMS (micro-electromechanical systems), to provide highly sensitive and accurate force measurements. By miniaturizing the sensing elements, micro force sensors are able to capture the subtle changes in forces that are essential for a wide range of applications.

Importance of Precise Force Measurement

Precise measurement of tiny forces is critical across many fields. In robotics, these sensors help control grip strength and object handling. In healthcare, they’re used in prosthetics and surgery to ensure safety and effectiveness.

They’re also crucial for studying materials and biological processes at very small scales.

Applications of Micro Force Sensors

These sensors are used in many industries, including:

- Robotics and automation

- Biomedical devices and instrumentation

- Scientific research and laboratory equipment

- Automotive and aerospace systems

- Precision manufacturing and quality control

- Tactile sensing and human-machine interaction

- Micro/nano-scale material characterization

They make leaps in these fields by offering reliable force measurement. This drives innovation and broadens possibilities.

Principles of Operation

Micro force sensors use two main methods to measure force: capacitive force sensing and piezoresistive force sensing. These methods help the sensors work well in many areas where knowing precise force is important.

Capacitive Force Sensing

Capacitive force sensors look at how close two electrodes are. They measure the change in this closeness when force is applied. The closer the electrodes get, the more their capacitance changes. This lets the sensor figure out the force amount. So, capacitive force sensors are very good at noticing small forces really well.

Piezoresistive Force Sensing

Piezoresistive force sensors focus on how a material’s electrical resistance changes under force. Applying force changes the material inside the sensor. This change in form adjusts the material’s resistance. As a result, piezoresistive force sensors are very good at giving precise force values. Consequently, they work in many areas, from robotics and automation to biomedical devices and the automotive industry.

Micro Force Sensor Technologies

XJCSENSOR uses top micro force sensor tech for accurate and reliable force measurement. It offers MEMS, capacitive, and piezoresistive force sensors. Each has its own benefits, meeting needs across industries. XJCSENSOR picks the best tech for each situation, for great performance and dependability.

MEMS Force Sensors

MEMS force sensors use tiny, built-in parts to measure force very accurately. They turn force into electrical signals using mechanical and electrical parts, like thin membranes or cantilevers. Because of their small size, low energy use, and durability, they fit well in robotics, medical tools, and industrial settings.

Capacitive Force Sensors

Capacitive sensors work by measuring changes in electric capacitance under force. They have plates that change distance when pushed, altering capacitance. These sensors are highly sensitive, quick to react, and very accurate. They are perfect for tasks needing precise force readings such as in pressure sensing or weight measurement.

Piezoresistive Force Sensors

Piezoresistive force sensors change their electrical resistance under force, using the piezoresistive effect. They have elements like strain gauges that change resistance when pushed. Piezoresistive sensors are tough, stable, and perform well in many conditions. They’re great for use in industry and transportation, plus for monitoring structures.

micro force sensor

Micro force sensors are vital in many fields like robotics and automation, biomedical devices, and the automotive industry. They offer precise and reliable force measurement. This allows for accurate data collection and control in tough settings. XJCSENSOR is a top producer of micro force sensors, offering various solutions for today’s industries.

XJCSENSOR’s micro force sensors use cutting-edge technologies, including MEMS (micro-electromechanical systems), capacitive, and piezoresistive methods. They ensure outstanding performance and dependability. These sensors can measure minute forces accurately. This makes them key for tasks needing precise force measurement, such as tactile sensing and strain analysis.

Working with XJCSENSOR gives clients access to a wide array of micro force sensor choices. Whether for robotics, biomedical devices, or the automotive industry, XJCSENSOR’s experts offer advice and support. They aim for smooth sensor use and top performance.

Advantages of Micro Force Sensors

Micro force sensors have several major benefits, making them perfect for many uses. They’re built to be extremely precise and accurate. This means they can measure small forces very dependably at the micro-level.

High Precision and Accuracy

Micro force sensors use cutting-edge design and technology. They can detect even the tiniest of forces with amazing accuracy. This is key in areas like robots, medical tools, and scientific study.

Compact and Lightweight Design

These sensors are small and light, fitting easily in tight spots. This is great for places where size and weight matter, like in robotics. It also works well in medical devices and auto tech.

Wide Range of Applications

Micro force sensors are super versatile, fitting in lots of industries, including cars and space. They can be adjusted to tackle many different jobs. This ensures they give just the right force readings needed. They really push innovation and development forward.

Force Measurement Challenges

Micro force sensors are very precise and reliable. But, they can run into some issues in the real world. Things like temperature, humidity, and vibration can mess with their accuracy. It’s crucial to calibrate sensors well to keep force measurements reliable over time.

Environmental Factors

These sensors work in all kinds of places, each with unique problems. Changes in temperature can cause the sensor not to measure forces right. High humidity might make water droplets form inside, which can mess with the sensor. Vibration in places like factories can add extra noise to the readings.

Sensor Calibration

Keeping micro force sensors accurate needs regular checks. This includes making adjustments to counter any changes over time. XJCSENSOR has a top-notch team that works on the design and testing. They make sure the sensors work great everywhere they’re used.

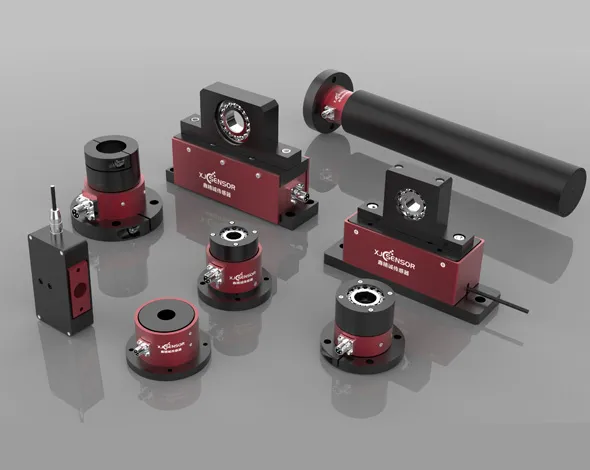

XJCSENSOR’s Micro Force Sensor Solutions

XJCSENSOR is a top maker of micro force sensors. They provide many types to serve various customer needs. Their range covers different micro force sensors, all for specific uses.

Product Range

At XJCSENSOR, you can find compression force transducers, tension force transducers, and more. These devices give accurate and dependable force measurement, meeting needs across many areas.

Custom Solutions

Engineering pros at XJCSENSOR collaborate with customers for precise micro force sensor solutions. This close teamwork ensures clients get the right micro force sensing tech for their projects. It helps drive their innovations forward, meeting their specific needs.

Applications of Micro Force Sensors

Micro force sensors are used in many industries, showing how diverse they are. They help with precise measurements and control. This is key to making new tech and innovations happen.

Robotics and Automation

In robotics and automation, these sensors are crucial. They help with exact force control and give tactile feedback. This is important for tasks like handling objects, assembly, and when working with delicate items.

Biomedical Devices

The medical field depends a lot on micro force sensors. They are in medical devices, prosthetics, and surgical tools. These sensors help ensure patient safety and how well treatments work by giving accurate readings.

Automotive Industry

Cars also use micro force sensors. They’re for tracking brake forces, analyzing suspensions, and controlling vehicle dynamics. With precise data on forces, cars can be safer and perform better.

| Application Area | Key Applications of Micro Force Sensors | Sensor Technology |

|---|---|---|

| Robotics and Automation | Object manipulation, assembly, and delicate handling | Capacitive, piezoresistive, and MEMS force sensors |

| Biomedical Devices | Medical devices, prosthetics, and surgical instruments | Capacitive and piezoresistive force sensors |

| Automotive Industry | Brake force monitoring, suspension analysis, and vehicle dynamics control | Piezoresistive and load cell force sensors |

Integration and Implementation

Integrating and implementing micro force sensors is key. Experts at XJCSENSOR help choose the best sensor for each need. They ensure it matches the application’s specific needs. They also aid in signal processing and data acquisition, making sure the sensors work smoothly and provide the data you need. This way, customers get the most out of using micro force sensors.

Sensor Selection

Choosing the right micro force sensor is essential. XJCENSOR’s team deeply understands customer needs. They consider things like the force needed and the environment. Then, they recommend the best capacitive force sensors, piezoresistive force sensors, or others for the job.

Signal Processing and Data Acquisition

After choosing the sensor, XJCSENSOR helps with signal processing and data acquisition. They offer support for circuit design and data analysis. This support means customers can effectively use their sensor data. It helps them move their applications ahead.

Future Trends in Micro Force Sensing

The world of micro force sensing is always changing. New technologies and uses are appearing. The experts at XJCSENSOR are watching closely. They study new things like nano-scale force measurements and sensors that work without wires. These can be used in many fields, from robots to healthcare and making things.

Emerging Technologies

Technology for measuring tiny forces is getting better at XJCSENSOR. They are excited about new tools, like sensors that can see things at the smallest level and those that don’t need wires to work. These new tools will help measure forces more exactly. They will be used in robots, healthcare devices, and making things better.

New Application Areas

The use of small force sensors is getting better and better at XJCSENSOR. They expect these sensors to be used in new places. For example, they could improve how we interact with computer simulations or make homes and factories smarter. XJCSENSOR is leading this change. They help their clients use the newest force-sensing technologies to make their own ideas come to life.

Conclusion

Micro force sensors are key in many industries, offering precise force measurements. This is crucial for innovation and pushing tech further. XJCSENSOR shines in this field, with many solutions meeting varied customer needs. It uses top-notch sensor tech and deep industry knowledge to create sensors that meet market demands.

These sensors are used in robotics, health tech, and cars, showing their wide use. XJCSENSOR focuses on innovation and helping its clients with advanced sensing technology. It’s ready for changes and new uses in micro force sensing, aiming to be the top choice for tech progress.

XJCSENSOR sets itself apart by focusing on precision, reliability, and custom solutions. Its sensors help clients improve their products and services, spurring innovation. As the need for accurate measurement increases, XJCSENSOR vows to lead this area by delivering groundbreaking micro force sensing solutions.