Introduction: The axial load cell is a critical component in the field of force measurement, enabling precise and efficient monitoring of axial forces. This article delves into the functionality, applications, benefits, and considerations when using axial load cells. Discover how these advanced sensors contribute to improved accuracy, reliability, and performance in various industries.

Understanding Axial Load Cells: Axial load cells are designed to measure forces applied along a single axis, providing accurate readings of tensile or compressive loads. They utilize strain gauges that convert mechanical stress into electrical signals, which are then calibrated and translated into force measurements. The robust construction of axial load cells ensures durability and long-term stability, making them suitable for demanding environments.

Applications of Axial Load Cells: Axial load cells find numerous applications across different industries:

- Industrial Manufacturing: Axial load cells play a pivotal role in quality control, ensuring proper tension and compression forces in materials during manufacturing processes such as assembly, testing, and material handling.

- Automotive Industry: These load cells are employed in vehicle crash tests, structural integrity analysis, and suspension system testing to measure forces accurately and ensure safety compliance.

- Aerospace and Defense: In aerospace applications, axial load cells are used to monitor forces in aircraft components, rocket engines, and satellite deployment mechanisms, ensuring optimal performance and reliability under extreme conditions.

- Material Testing and Research: Axial load cells facilitate material testing by measuring the strength, elasticity, and deformation characteristics of various materials, aiding in research and development efforts.

- Construction and Civil Engineering: These load cells are utilized for monitoring and optimizing the loading capacity of structures, bridges, and building foundations, guaranteeing safety and durability.

Benefits of Axial Load Cells: Axial load cells offer several advantages that contribute to improved force measurement:

- High Accuracy: The strain gauges in axial load cells provide precise and reliable force measurements, ensuring accuracy in critical applications.

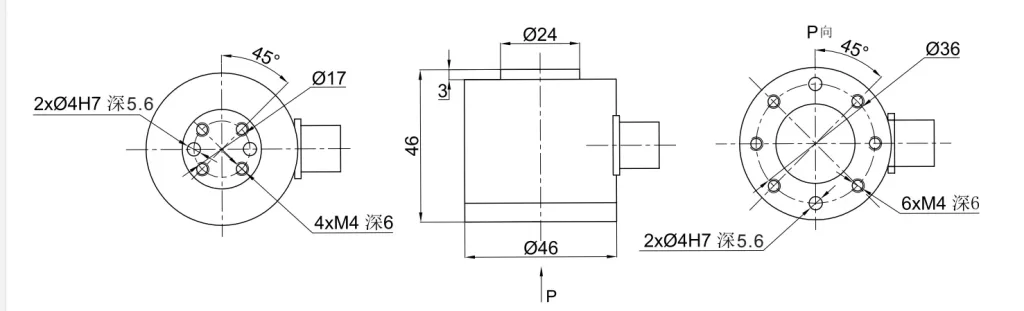

- Compact Design: With their compact size, axial load cells can be easily integrated into existing systems or confined spaces, maximizing flexibility and ease of installation.

- Wide Measurement Range: These load cells offer a broad range of force measurement capabilities, catering to varying requirements across industries.

- Durability and Longevity: Constructed with robust materials and designed to withstand harsh environments, axial load cells demonstrate excellent durability and long-term stability.

Considerations for Axial Load Cells: When selecting axial load cells, consider the following factors:

- Capacity and Range: Choose a load cell with an appropriate capacity and range that aligns with your specific application needs.

- Accuracy and Precision: Evaluate the load cell’s accuracy specifications to ensure it meets the required precision levels for your measurement requirements.

- Environmental Factors: Consider the operating conditions such as temperature, humidity, and potential exposure to chemicals or vibrations to select a load cell suitable for the environment.

- Calibration and Maintenance: Regularly calibrate and maintain the axial load cells to preserve their accuracy and extend their lifespan.

Conclusion: Axial load cells are indispensable tools in force measurement, providing accurate and reliable data for a wide range of applications. Their ability to enhance accuracy, efficiency, and safety makes them valuable assets across various industries. By understanding the functionality, applications, benefits, and considerations associated with axial load cells, businesses can make informed decisions when incorporating these sensors into their force measurement systems, ultimately improving overall operations and outcomes.