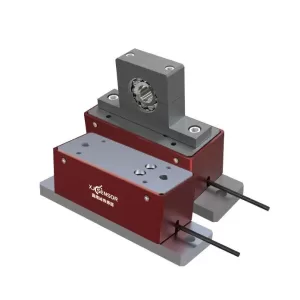

X-ZL05 Series Cantilever Tension Sensor

It designed for installation equipment of single-side cantilever roller. It is integrated with cantilever shaft and roller components, so no special design required for the roller. Tension can be detected by inserting a spare roller into the cantilever tension detector. It can be used to measure and control the tension of materials during processing.

Category

X-ZL05 Series Cantilever Tension Sensor

Features

● Easy to install;

● High precision, detection signal is not affected by the position of the coil;

● Accurate measurements even under low tension;

● Built-in new mechanical 10 times anti-overload protection;

● Minor temperature drift, good linear error and repeatability error, small size, little space required for installation;

● Standard M12*1 plug

Description

XJC-ZL05 series cantilever tension sensor is designed for installation equipment of single-side cantilever roller. It is integrated with cantilever shaft and roller components, so no special design required for the roller. Tension can be detected by inserting a spare roller into the cantilever tension detector. It can be used to measure and control the tension of materials during processing, such as paper, label, tape, battery electrode, high performance film and other narrow materials . The sensor’s detection signal will not be affected by the position of the coil on the roller.

Technical Parameter

| Rated output | 1.0±10%mV/V | Non-linearity | 0.2% F.S. |

| Repeatability | 0.1%F.S. | Zero balance | ±2% F.S. |

| Operating temp range | -20~80°C | Compensated temp range | -10~40°C |

| Temp effect on zero | 0.02%F.S/°C | Insulation | ≥2000MΩ/100VDC |

| Recommended excitation voltage | 5~10VDC | Limit load | 1000%F.S. |

| Cable size | φ5x5m | Protection class | IP65 |

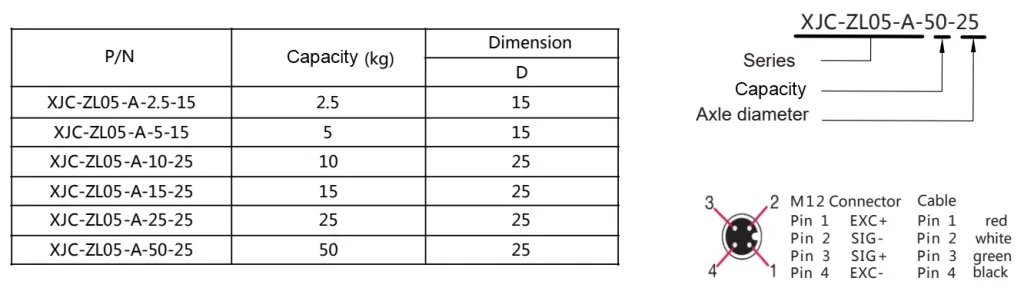

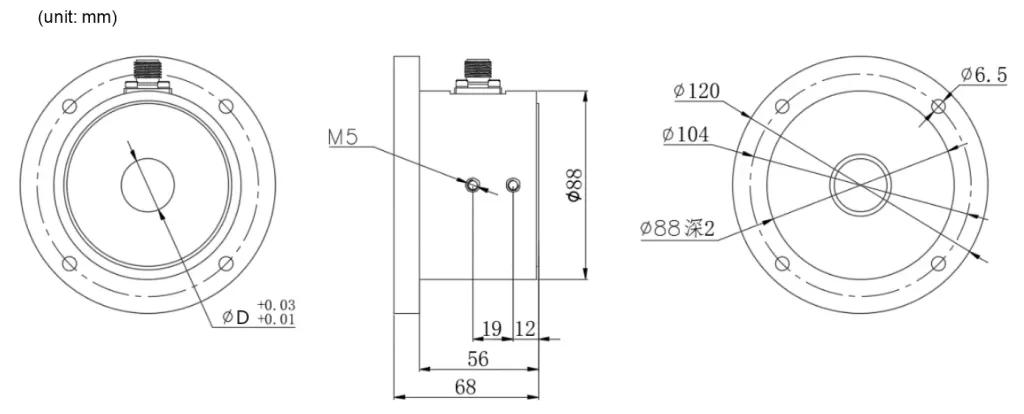

Dimensions

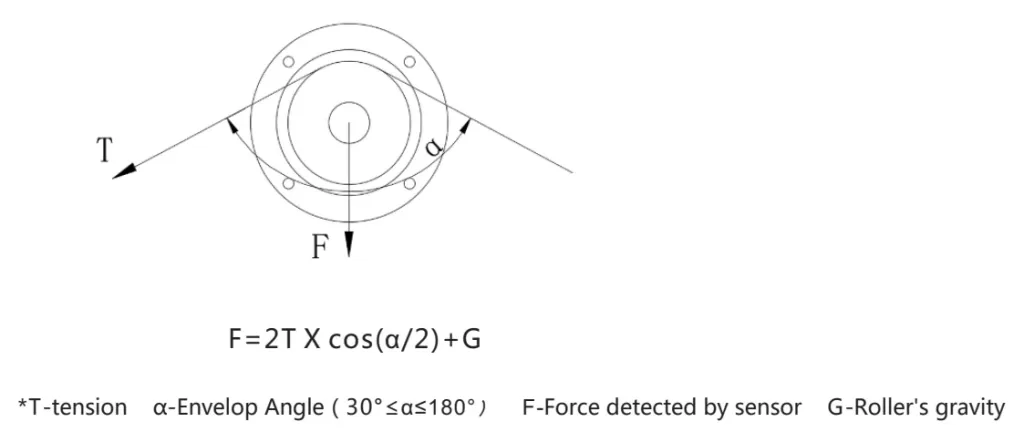

Force calculation

Installation

Installation methods are as follows

NOTE: When installing the shaft and roller assembly on the cantilever tension sensor, make sure it does not interfere with the cantilever tension sensor housing or the machine’s wall panel. The diameter of the clearance hole on the machine’s wall panel is at least 1.5mm larger than the shaft hole, tighten the four screws to the shaft.

Naming Rules