Do you ever wonder how industries measure force and torque accurately in three dimensions? The 6 degree of freedom force transducer tells us how. It uses advanced technology for precise measurements across different axes. This helps in important industrial work where 3D force vectors are needed.

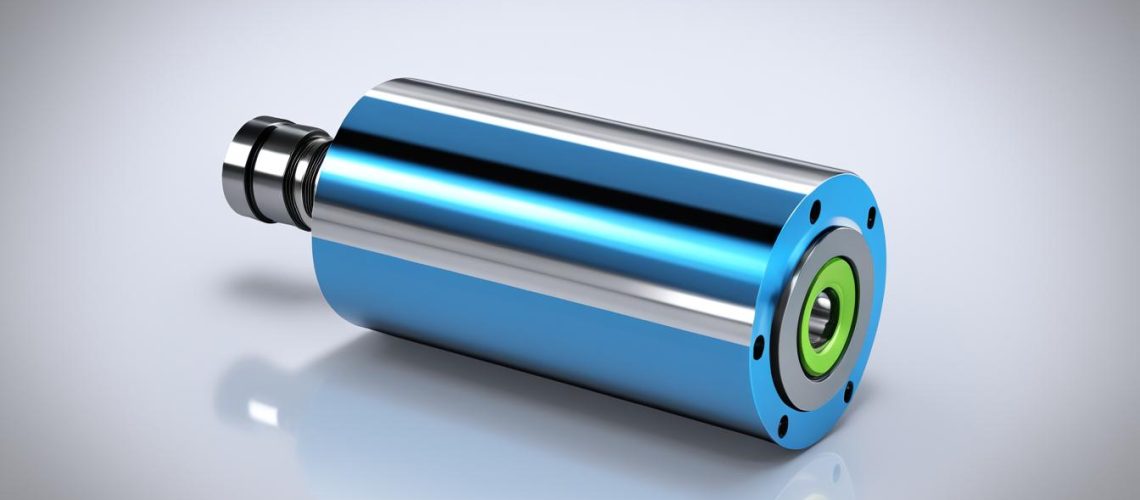

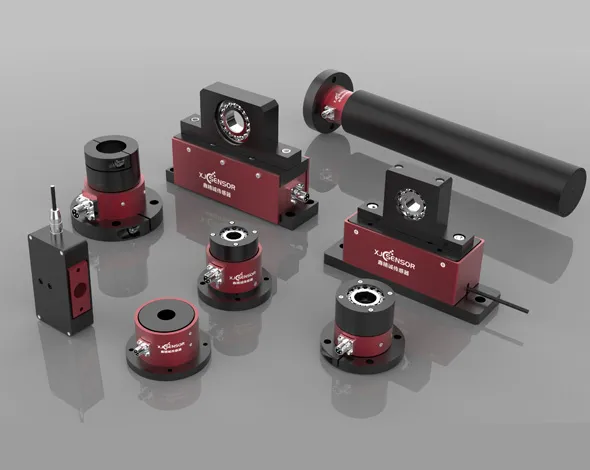

XJCSENSOR leads in making high-quality, multi-axis load cells. These 6 dof load cells are known for their precision and reliability. They are essential for making sure measurements in complex scenarios are as accurate and safe as possible.

Key Takeaways

- 6 DoF load cells measure precise force and torque across multiple axes.

- These sensors are crucial for intricate industrial applications.

- They provide detailed analysis of force vectors in three-dimensional space.

- XJCSENSOR is recognized for their high-quality multi-axis load cells.

- 6 axis load cells from XJCSENSOR cater to a wide range of industry requirements.

Introduction to 6 DoF Load Cells

In today’s world, technology has advanced greatly. This change is visible in fields such as force and torque measurement. The new 6d load cells are now a key part. They are precise and versatile. These load cells measure forces and torques in three dimensions. They also measure the rotations around the axes. It is worth looking into what makes a 6 DoF sensor and how it is used.

What is a 6 DoF Load Cell?

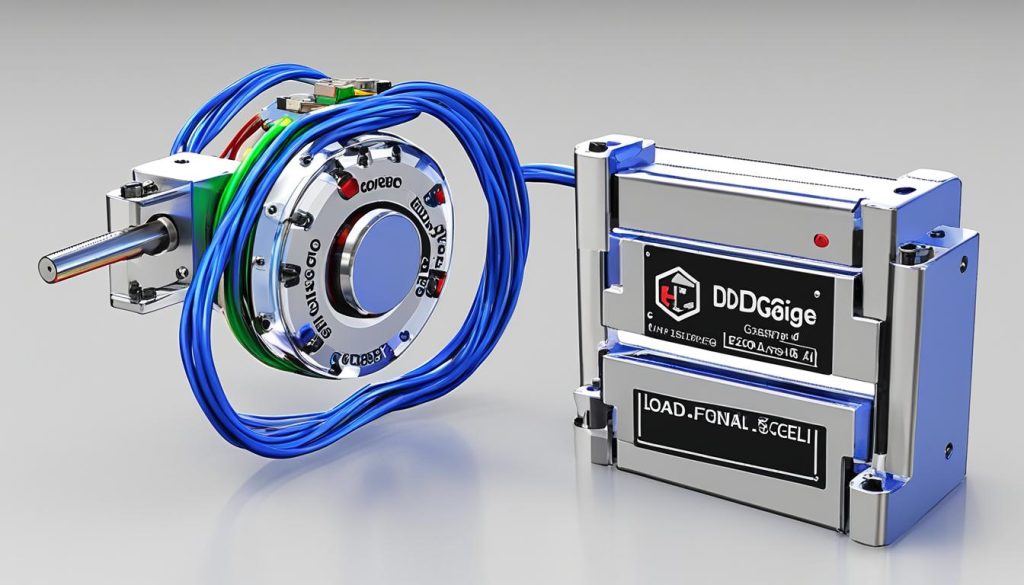

A 6 DoF load cell is a complex device. It can take three-dimensional force vectors and torque and turn them into data. These devices are part of the smaller group of multiaxis load cells. They make up just 0.1% of the load cell market. They often use many strain gages, with some having more than 32 of them. This adds to the production cost.

- Material Usage: For lower force ratings and cost efficiency, aluminum is often used, while higher loads are sustained with titanium or stainless steel.

- Sensor Sizes: Sizes vary from 4 to 7 inches containing three to four load-carrying elements known as strain rings, and can reach up to 16 strain rings in custom 20-inch sensors.

- Load Ratings: These sensors have load ratings from under 10 to over 25,000 lb, with moment ratings ranging from 2 to 150,000 ft-lb, showcasing their extensive application capabilities.

Applications of 6 DoF Load Cells

The use of 6 dof load cells is broad and varied. They are needed in industries where knowing force and torque exactly is crucial:

- Robotics: In the world of robots, 6d load cells make control and feedback better. This helps with more accurate movements and steadiness in the robots’ arms and systems.

- Aerospace: In air travel tests and structure checks, these sensors are vital. They help engineers check the forces and moments parts of planes face under many circumstances.

- Automotive Testing: Precision in force measuring is important in car testing and performance checks. This work helps create safer and more efficient cars.

To sum up, 6 dof sensor solutions offer a step forward in many areas. They improve precision and control in tough jobs. They are used in places like robotics, aerospace, and cars. Their use means getting data that is exact. This helps with detailed study and better results in operations.

How Does a 6 DoF Load Cell Work?

A load cell for 6 degrees of freedom is precise in measuring force and torque. It measures three forces and three moments. This is key for precise force measurement in many industries.

Principles of Operation

At its heart, a 6 DoF load cell uses strain gauges. These gauges detect changes when loads are applied. They change electrical resistance as loads vary, enabling precise force and torque readings.

Design and Structure

The design of a load cell for 6 degrees of freedom is key. It uses durable materials and precise gauge placements for reliability. This design allows for accurate measurements even with complex loads.

| Feature | Function | Benefit |

|---|---|---|

| Strain Gauges | Detect deformation | Highly sensitive to changes, ensuring accurate force measurement |

| Multi-Axis Capability | Measures in three spatial dimensions and rotational axes | Comprehensive torque analysis and force assessment |

| Robust Materials | Constructed from high-strength materials | Durability and longevity in industrial use cases |

Advantages of Using 6 DoF Load Cells

6 DoF load cells bring big benefits in measurement accuracy and how they can be used. They are key in recording and studying force and torque very accurately.

High Accuracy and Precision

A high accuracy 6 dof load cell shines in delivering exact measurements. It spots tiny changes in force and torque, making all info trustworthy. Such high precision is pivotal where small errors can have big effects.

Versatility and Flexibility

Versatile force measurement is a huge plus with 6 DoF load cells. They can work in many fields, like aerospace and robotics. This adaptability goes further; they can be personalized for particular industrial needs, offering fitting answers to various measuring tasks. So, they’re perfect for many scenarios, from daily checks to detailed research.

| Advantage | Description |

|---|---|

| High Accuracy | Provides precise measurements, capturing small force and torque changes. |

| Versatility | Adaptable for use in multiple industries and customizable as needed. |

| Reliable Data | Ensures consistent and dependable readouts for critical applications. |

| Customization | Tailor-made designs to suit specific usage scenarios and environments. |

By choosing 6 DoF load cells, you get great precise torque analysis and flexibility in measuring force. This mix assures these sensors are up to any tough task.

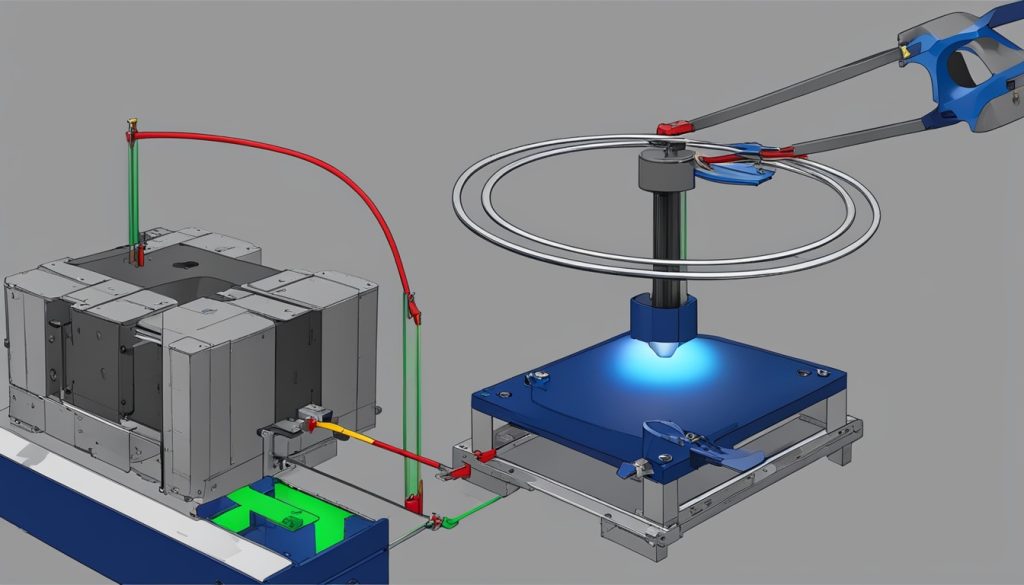

Applications in Robotics

Robotics has rapidly evolved with the help of 6 DoF load cells. These are crucial for precise force and torque measurements. These sensors bring advanced force control to many applications, improving their performance.

In manufacturing, *robotic force measurement* is key for assembly tasks. The quality of the final product depends on the exactness of force application. With *6 degree of freedom force transducers*, robots can handle complicated assembly jobs better, reducing mistakes.

In research, these sensors allow in-depth testing of robot systems. They help measure forces and torques in various directions. This ability lets researchers enhance the performance of robotic arms. It leads to new developments in automation and AI.

“The implementation of 6 DoF load cells has revolutionized our approach to robotic force measurement,” says a leading robotics engineer at Boston Dynamics. “The precision they offer is unparalleled, driving forward our capabilities in both development and deployment of robotic systems.”

Training new robots also heavily depends on accurate *robotic force measurement*. Knowing the precise forces involved helps create robots capable of many tasks. These robots are more like humans in their ability to respond and adapt.

| Application | Benefits |

|---|---|

| Manufacturing | Increased precision, reduced error rates, enhanced quality control |

| Research | Detailed performance analysis, innovation in automation and AI |

| System Training | Improved responsiveness, adaptive task management, human-like dexterity |

Summing up, 6 DoF load cells greatly improve robotics. They make current applications more effective and open the door for new tech. By providing accurate *robotic force measurement*, these sensors are essential for the progress of robotics.

Applications in Aerospace

In the aerospace industry, 6 DoF load cells are very important. They help with very accurate aerospace load measurement and structural analysis in aerospace. These tools are crucial for engineers. They track the force and twisting on aircraft parts. This ensures aerospace structures work safely and well.

Flight Testing

6 DoF load cells are key in flight tests. They show how planes move and handle. These sensors measure forces and twists in three ways. This lets engineers copy real flight conditions. They then use this data to make sure planes are designed and work better. For example, the M35 sensors are thin and sensitive, giving important accurate data for testing.

Structural Analysis

Structural analysis is vital for checking aircraft parts. 6 DoF load cells help find weak spots and how weight is spread in plane parts. They make sure aircraft are safe enough. These sensors are very precise, with errors less than 1%. They are reliable for checking if the plane parts are strong enough.

| Feature | Detail |

|---|---|

| Thickness | Less than 1cm; smallest at 7.5mm |

| Weight | Less than 0.26kg; lightest at 0.01kg |

| Non-linearity and Hysteresis | 1% |

| Crosstalk | Less than 3% |

| Number of Models | 18 |

SRI sensors offer top quality at a good price. They are used in the US, China, Canada, and more. Over the past seven years, they have proven their worth in aerospace load measurement tasks. This shows how valued they are in this industry.

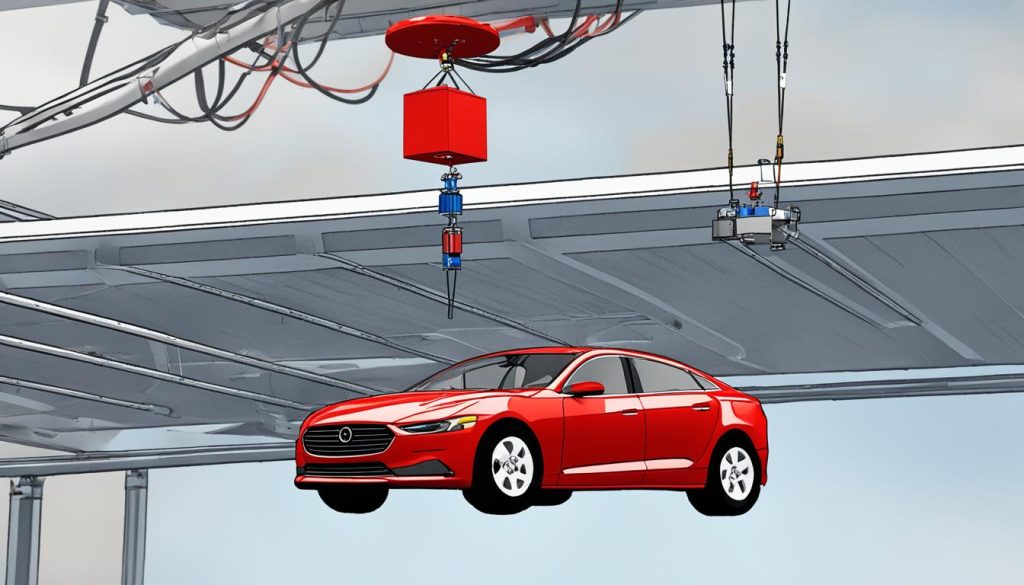

Load Cell for 6 Degrees of Freedom in Automotive Industry

In today’s fast-moving automotive world, getting force measurements right is key. A 6 DoF load cell is vital for many tasks, like crash tests and checking how well a car performs. It looks closely at how cars handle different forces, offering lots of detailed info.

Crash tests rely heavily on these sensors. They show exactly what forces and twists happen when a car hits something. This helps engineers make cars safer for us. By using a force transducer for the automotive industry, essential safety data is collected. This helps make cars safer year after year.

6 DoF load cells also help a lot with testing car performance accurately. They give a deep look at how a car moves under all kinds of situations. With safety and performance high on car buyers’ lists, these advanced sensors are a must. They’re key in making sure cars not only meet standards but also go beyond what we expect.

Comparing 6 Axis Load Cells with Traditional Load Cells

It’s key to understand the differences between 6 axis load cells and traditional types. This helps in picking the right force measurement solution. We will explore what makes them different.

Differences in Measurement Capabilities

Why are 6 axis load cells and traditional ones not the same? Well, traditional cells measure force in just one direction or plane. But 6 axis cells can measure forces and torques in six ways. This includes force vectors in three-dimensional space.

This extra ability helps understand forces better. It’s great for precision and complex needs.

Differences in Applications

6 axis load cells have a wider measurement range. This makes them better for many tasks. Traditional cells work well in simple, single-axis jobs. But the benefits of 6 axis cells really shine in complex situations.

For tasks like robotic control and aerospace work, 6 axis cells are needed. They add value where traditional cells can’t do enough.

Choosing the Right 6 DoF Load Cell

When selecting a 6 DoF load cell, you must consider several key factors. This ensures the load cell fits your needs perfectly. Picking the right one is more than just about accurate measurements. It also affects how long your equipment lasts and its reliability.

Factors to Consider

When picking a 6 DoF load cell, key things to think about are its measuring range, how accurate it is, and where you’ll use it. These factors are super important for the load cell to work well in all kinds of situations.

- Measurement Range: Make sure the load cell can handle the biggest load you plan to measure.

- Accuracy: Choose a load cell that’s super precise to cut down on measurement mistakes.

- Environmental Compatibility: Think about where you’ll use it. This includes things like the temperature and if it will be around things that corrode.

Specifications to Look For

It’s essential to understand load cell specifications for the right choice. Knowing these specs helps figure out if a load cell fits your needs. This includes how well it performs for specific jobs.

| Specification | Description |

|---|---|

| Capacity | The top load the cell can measure correctly. |

| Accuracy | How close the measured values are to the actual ones. |

| Sensitivity | Lets you know the signal strength for the force used. |

| Temperature Range | The load cell’s effective operating temperature range without losing accuracy. |

| Output Signal | The electric signal you get from the measured force or torque. |

| Material | The material used that affects how sturdy and resistant the load cell is. |

By looking closely at these load cell specifications, you can choose wisely according to your specific needs. Picking a 6 DoF load cell that meets these standards leads to strong and reliable performance in your application.

High Accuracy 6 DoF Load Cells: XJCSENSOR’s Offerings

We have a range of XJCSENSOR load cells that promise top-notch precision measurement solutions. These load cells are top-notch when it comes to high accuracy. They can spot even the tiny changes in force and torque. This makes them a must-have in industries that need precise data.

XJCSENSOR load cells are known for their strong technology. This makes them last a long time and work well in different settings. Before they reach you, each sensor is tested thoroughly to make sure it meets top quality standards. So, they keep performing well over time.

“Utilizing XJCSENSOR load cells has tremendously improved our precision measurement capabilities, providing us with the data accuracy necessary for our complex applications,” said a happy customer from the aerospace industry.

XJCSENSOR also offers customization options. This means we can create precision measurement solutions that are exactly what our clients need. This ability to customize ensures that the solutions meet your specific industry requirements perfectly.

| Feature | Benefit |

|---|---|

| High Accuracy | Ensures precise force and torque readings |

| Robust Technology | Reliable performance across various conditions |

| Customization | Tailored solutions for specific industry needs |

Maintaining and Calibrating Your 6 DoF Load Cell

Making sure your 6 DoF load cell lasts long and remains accurate relies on how well you care for it. We’ll look into why keeping it in good shape is so important, and what steps you should take to calibrate it the right way.

Importance of Regular Maintenance

Keeping up with the load cell maintenance is key to keeping your 6 DoF load cell reliable. If you don’t check it often, it might start giving wrong readings. It’s crucial to check for any breakage, rust, or changes in shape. Also, keep the sensor and its area clean to prevent wrong measurements due to dirt.

Calibration Procedures

Calibration of force transducers is crucial for correct measurements of force and torque. Only experts should calibrate it using special weights and tests. Doing this makes sure your load cell meets the set standards. During calibration, the load cell is tested with known weights. If the readings are off, the experts adjust it to be right. This step makes the measurements you get more trustworthy.

Here’s a quick look at what a basic calibration plan involves:

| Calibration Task | Frequency |

|---|---|

| Visual Inspection | Monthly |

| Cleaning | Quarterly |

| Full Calibration | Annually |

| Professional Recalibration | Every 2 Years |

Regular load cell maintenance and strict calibration of force transducers make your equipment last longer and stay accurate. This approach leads to better and more reliable data for your work.

Conclusion

At the end of this study, we see 6 DoF load cells are vital for accurate force measurement. They are critical in fields like robotics, aerospace, and car testing. These cells can measure force and torque in six ways, which is crucial.

These special sensors make precision better. They give detailed data for control and analysis needs. You can see their use is wide, and they are important in engineering and research today.

XJCSENSOR is known for top-notch 6 DoF load cells. They focus on innovation and precision. Their products meet today’s tough industry demands. Using their solutions in your work means getting accuracy and strength for success.