Ever wondered how big industries get their weight measurements so precise? They use a top-of-the-line 10 ton load cell for accuracy. In the industry world, getting the weight exactly right is crucial. Many sectors rely on this secret weapon to measure weight properly.

A 10 ton load cell is crucial in weight-sensitive areas. It works as a super accurate sensor for big loads. A high-quality load cell is very important because a small mistake in measuring can be very bad. It can cause problems in daily work, create dangers, and raise costs.

In sectors like building, moving goods, and making things, load cells are key. Getting measurements right is not optional but a must. Picking the best load cell greatly improves how well and safely tasks are done. It’s a vital part of solving measurement issues in the industry.

Key Takeaways

- A 10 ton load cell is vital for accurate weight measurement in industrial applications.

- High-quality load cells enhance operational efficiency and safety.

- Load cells play a key role in numerous industries including construction and manufacturing.

- Even slight inaccuracies in weight measurement can lead to costly and dangerous outcomes.

- Investing in top-rated, heavy duty load cells ensures reliability and precision.

Introduction to 10 Ton Load Cells

The 10 ton load cell is key in many industries for measuring weight accurately. This accuracy is vital for safety and keeping operations running smoothly. To truly understand load cell tech, we must see its function in various places.

What is a Load Cell?

A load cell turns force into an electric signal. It uses strain gauge tech to measure deformations under loads. This allows for exact weight measurement, crucial in many fields like manufacturing and transport. It keeps weight records spot-on.

Importance of Accurate Weight Measurement

Getting weights right is crucial in industry. Even small errors can cause big problems. Accurate load cells help in quality control, ensuring products are top-notch.

They also stop overloading and equipment breakage, keeping people and work areas safe. Plus, it cuts waste and boosts efficiency, saving money.

Industrial Load Cells: An Overview

Industrial load cells are key in many fields, making sure we measure things right. They come in different types, each playing a big part in various industries.

Types of Industrial Load Cells

Load cells vary to fit different needs. For instance, there are:

- Bending Beam Load Cells: They work great in systems that measure things in motion.

- Compression Load Cells: They handle weight in applications where things are firmly supported.

- S-Type Load Cells: Ideal for checking how much something is pulling or pushing.

- Canister Load Cells: These are for recording very heavy loads.

- Single Point Load Cells: They’re perfect for making platform scales very accurate.

Applications in Various Industries

Each industry uses load cells in unique ways. For example, they help in:

- Construction: Making sure structures are built safely and accurately.

- Transportation: Checking the load’s weight for safety and rules.

- Manufacturing: They improve making things by controlling their weight well.

- Aerospace: In planes, they are crucial for keeping the right weight and balance.

Recognizing the value of these tools is vital for accurate and reliable measuring in industries. They are an essential resource, improving how various fields work and stay safe.

Choosing the Right 10 Ton Load Cell

Deciding on the correct 10 ton load cell is very important. It involves looking at many criteria. The right choice leads to high performance and reliability in different industrial uses.

Factors to Consider

Several factors are important when picking a 10 ton load cell. Think about the environment it will work in and what kind of load it will measure. Consider the need for precision too.

How easy it is to set up and maintain matters as well. Pick the right one to avoid future issues and boost your system’s efficiency.

Material and Build Quality

The materials and making of a load cell greatly affect its toughness and how well it works. Strong materials like stainless steel or aluminum make load cells last longer and give accurate results.

The way a load cell is built also matters. It should be tough enough for rough settings and frequent use.

Choosing load cells made from top-tier materials ensures they last and do their job well. Make sure they meet the industry’s quality and safety standards. This helps in choosing the best 10 ton load cell for your needs, guaranteeing success over time.

| Factor | Importance |

|---|---|

| Environmental Conditions | Ensures load cell can operate in specific climates and surroundings. |

| Load Type | Matches the load cell’s capabilities with the application’s requirements. |

| Accuracy Requirements | Assures precise and reliable measurements. |

| Material and Build Quality | Enhances durability and performance in demanding environments. |

Top Features of High Capacity Load Cells

High capacity load cells are key in many industries. They allow us to weigh heavy items precisely and reliably. Here we explore their top features for industrial use.

Durability and Reliability

For high capacity load cells, being tough and reliable is key. They work in tough conditions, against moisture, chemicals, and changes in temperature. Vibrations are no problem for them. Their strong design ensures they stay accurate and long-lasting despite these challenges.

Precision and Sensitivity

Key features of these cells are precision and sensitivity. These cells can measure very precisely, whether it’s push, pull, or pressure. They use advanced tech to be very sensitive and ensure tiny changes in weight are noticed. This is important for very accurate work.

“Load cells can handle various types of stress, including normal stress that can be tensile or compressive, shear stress, and torsion. Each type of stress acts differently within the load cell, ensuring precise measurement across different applications,” experts from Tacuna Systems affirm.

Here is a detailed comparison of some notable load cell features:

| Feature | Description | Importance |

|---|---|---|

| Durability | Resistant to environmental factors and heavy usage | Ensures long-term reliability |

| Precision | Accurate measurement of applied forces | Critical for quality control |

| Sensitivity | Detection of slight variations in load | Essential for detailed measurement |

| Load Cell Resilience | Withstands stress types such as shear and torsion | Versatile in application |

Top-Rated 10 Ton Load Cell Models

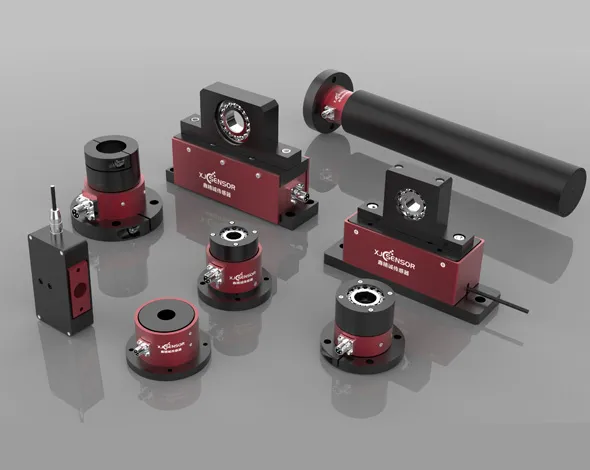

Many excellent 10 ton load cell models are available in the market. Some are highly rated because of their great features and performance. XJCSENSOR stands out for its reliability and advanced tech.

XJCSENSOR Model A

The XJCSENSOR Model A is known for precision and its durable build. It uses state-of-the-art strain gauge technology for accurate weight measurements. Its sturdy make handles tough industrial use.

- Key Features:

- High accuracy and repeatability

- Robust stainless steel design

- Splash-proof and dust-proof

- Optimized for long-term stability

XJCSENSOR Model B

The XJCSENSOR Model B is a top pick for its sensitivity and sturdy performance. It’s made with quality materials that can take on tough conditions. This ensures low error rates, making it a top load cell in the market.

- Key Features:

- Enhanced sensitivity for detailed measurement

- Rugged and compact design

- Anti-corrosion finish for longer life span

- Comprehensive calibration options

Picking the XJCSENSOR Model A or B means getting top-notch precision and reliability. These models merged advanced tech with durability. They are ideal for industrial needs, showcasing XJCSENSOR’s innovation.

Comparison of Heavy Duty Load Cells

When looking at heavy duty load cells, it’s key to know their key features. These features affect their performance a lot. We’ll discuss how the prices reflect the quality and use of these devices. This info will help our readers choose the best option for their money.

Performance Metrics

Several factors affect how load cell performance is viewed. For example, the ability to handle weight, how sensitive they are, and their toughness against the environment matter a lot. The best load cells handle these aspects well. This means they give accurate and dependable readings even in tough spots.

| Model | Load Capacity | Sensitivity | Environmental Resilience |

|---|---|---|---|

| XJCSENSOR Model A | 10 Tons | High | High |

| XJCSENSOR Model B | 10 Tons | Moderate | High |

Price vs. Value

Can you find good value in high-priced load cells? Well, sometimes, yes. Paying more at the start usually means better performance and longer use. But, lower priced options can still meet your weighing needs until you have more money. It’s about knowing the balance and picking what suits your job best.

Best Applications for Tension Load Cells

Tension load cells are very adaptable and accurate in industries that need precise weight measurements. They are used a lot in industrial weighing where getting the weight right is very important. Now, let’s look at where these cells work best.

Crane Scales: Crane scales is a big area where tension load cells are key. They measure weight very accurately, supporting the safety and smooth running of cranes. Tension load cells can also bear heavy weights, making them very reliable.

Hoisting Systems: Tension load cells are crucial in hoisting systems for accurate lifting and lowering heavy items. This use is common in construction, manufacturing, and shipping. It ensures the safety of the load being lifted or lowered.

Structural Load Testing: They are also critical in testing the strength of structures like buildings and bridges. Tension load cells help by measuring force, showing if a structure meets safety standards. They are an important part of ensuring these structures are safe and sturdy.

Tension load cells play a big role in many load cell applications, making industrial weighing more accurate and improving safety. They are key in cranes, structural testing, and more. Tension load cells help keep operations running smoothly and safely by providing accurate weight readings.

Compression Load Cells: Definition and Use

Compression load cells are key in precise weighing scenarios. They change a force into an electric signal. This signal is used in various fields like manufacturing and healthcare for reliable measurements.

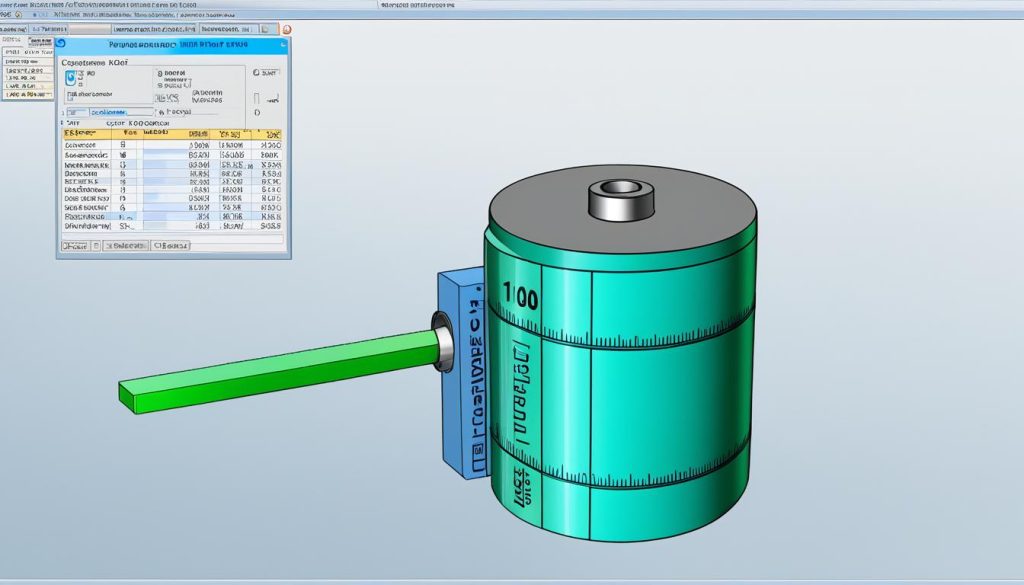

Understanding Compression Technology

These cells work with strain gauges and Wheatstone circuits. A load changes the strain gauge’s shape, which alters the electrical resistance. The Wheatstone circuit then turns this into a signal showing the force applied. This technology allows for very accurate weighing.

Common Applications of Compression Load Cells

Compression load cells are versatile, finding use in many areas. In industry, they help weigh vehicles for safety and rules compliance. For agriculture, they ensure silo stocks are recorded accurately. They also help in quality checking and certifications with testing equipment.

Transducer Techniques designs custom load cell solutions. They’re known for their fair prices and easy-to-use systems. Their products are perfect for accurate weighing needs.

Why Choose XJCSENSOR for 10 Ton Load Cells?

XJCSENSOR is a top choice for 10 ton load cells. Our focus on quality and meeting customer needs sets us apart. Many industries choose our load cells. Let’s see why.

Commitment to Quality

Quality is at the heart of everything we do at XJCSENSOR. Our team rigorously tests and checks each load cell. This ensures they meet strict industry standards. Our products are precise and reliable, perfect for tough jobs.

Customer Testimonials

Our clients’ happiness boosts our reputation. Here are some of their thoughts:

“XJCSENSOR’s load cells have significantly improved our operational efficiency. Their commitment to quality is evident in the reliability and accuracy of their products.” – A leading manufacturing company

“We have been using XJCSENSOR’s load cells for over a year now, and the customer satisfaction is unparalleled. Their support team is always responsive and helpful.” – A major construction firm

Testimonials show why customers trust XJCSENSOR. We are devoted to excellence and making our clients happy. With each load cell, we aim for quality and satisfaction.

| Aspect | XJCSENSOR | Other Brands |

|---|---|---|

| Quality Assurance | Extensive testing and standards compliance | Standard testing |

| Customer Satisfaction | High satisfaction rates and supportive service | Moderate satisfaction |

| Durability | Long-lasting and robust | Average lifespan |

Maintenance Tips for High Capacity Load Cells

Keeping your high capacity load cells in top shape is vital for their long use and precise readings. Checking them regularly helps them work well for longer.

Always start by looking for any wear and tear. Focus on the wires and connectors because they often wear out first. Fixing small issues early stops big problems later.

How you care for your load cells in their environment matters too. They need to stay away from too much heat, cold, dampness, and harsh chemicals. Using special covers can shield them. Also, store them right when not using them.

If you see the measurements are off, it might be time to adjust the load cells. Doing this might solve the problem. But if it keeps happening, you might need an expert to check or replace them.

It helps to stick to a set maintenance plan for your load cells. This includes regular checks and adjusting, as the maker recommends. This step ensures your readings are always right and trustworthy.

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Visual Inspection | Monthly | Early Detection of Wear |

| Environmental Protection Check | Quarterly | Prevents Environmental Damage |

| Troubleshooting and Calibration | Biannually | Maintains Accuracy |

To sum up, following these care tips and scheduling regular maintenance will do a lot to keep your load cells working well for longer. It’s important to look after our high capacity load cells so they stay accurate and reliable.

Conclusion

Exploring why a 10 ton load cell is important in many industries taught us a lot. We covered the basics of how load cell technology works. Then, we looked into what makes high-capacity load cells different.

It’s clear that getting weight measurements right is key for safety and efficiency. This is when choosing a quality measurement tool, like XJCSENSOR, comes in. They make top-notch 10 ton load cells. Their products support various applications and are very durable.

So, choosing XJCSENSOR means you get precise and reliable measurement tools. The guide showed that picking the best load cell involves many considerations. But with XJCSENSOR, you get superior quality and performance. We hope this information has been helpful in guiding your buying decisions for industrial weighing needs.